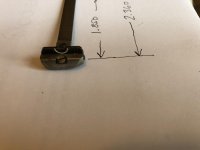

"paplinker"and I discussed this sight awhile back, and with very little prompting from him I came to also believe this might very well be a factory design---experimental at the time---or in VERY limited production immediately preceding the so-called "two screw" sight (the very first from S&W that won't "shoot loose" when properly adjusted and locked---Design #14 in Bob Neal's 1977 article (The Evolution of Smith & Wesson Target Sights)---which is available here on the forum-----somewhere.)

#14 won't "shoot loose" by virtue of the fact (when locked) the screw immediately in front of the aft screw is bearing against the frame, and the aft screw is pulling against frame (when properly adjusted and locked)---via a flange nut residing in a slot milled in the frame. What's noteworthy about the flange nut as it relates to this discussion is design #13 (which this sight appears to have been before it was modified) also employs a flange nut in concert with the elevation adjusting screw----never mind it's not pulling (or pushing) against anything---or is it?

I came to be acquainted with Neal after stumbling upon another rear sight not treated in the article (the Large Screw Spring Up model---(1911 to 1922-23). One thing led to another, and he asked me to update his article---as he had moved on to fascination with, and study of, something else, Packard automobiles or some sort of aircraft or marine engine of yesteryear. I decided to leave well enough alone, having no interest in seeming to be upstaging Bob on the one hand, and an entirely satisfactory update would be to simply change the dates on the sights following the Spring-Up sight.

The bottom line at this point is I have Neal's entire file which I supposed covered the research for the article performed by him and a legion of helpers, and offered to hunt it up to see if this sight here was found during the research-----and found in whatever numbers Neal determined to satisfactory---from the standpoint of the credibility he desired.

That proved to be easier said than done, but I finally found the file---just a few days ago, and it is not what I'd supposed it would be---which is to say there is no correspondence from Neal's helpers treating with their sightings/observations of the various sights. So much for that!

All that aside, that which suggests this sight may very well be either an experimental sight by S&W, or even a sight in (very limited) production is the supposition at this point that the elevation screw goes into a flange nut. Does it?

That being the case, this sight would work exactly the same as Design #14----just backwards in that the aft screw on this sight bears against the frame (if that's the case).

If (IF) this is either an experimental or limited production sight from S&W, they moved on to Design 14 for the very simple fact Design 14 costs less to manufacture than this one. Design 14 is Design 13 with one hole drilled and tapped in the sight tang--and an added screw (instead of milling a recess in the sight carrier for the aft screw, AND drilling and tapping the screw hole as is the case with this gun. The aft screw on this sight very likely bears against the frame, and if so, serves the very same purpose as does the screw immediately in front of the aft screw on Design 14.

Given that all this may be as clear as mud, here's how the "two screw" sight is to be adjusted and locked: Make the initial elevation adjustment with the aft screw---get close. Make the final elevation adjustment with the screw immediately in front of the aft screw. At this point, turn the aft screw counterclockwise as far as it will go. You're done! (The screw immediately in front of the aft screw is bearing against the frame. The aft screw (in concert with its flange nut riding in a slot milled in the frame) is pulling against the frame. Given that the aft screw on this gun bears against the frame, and the screw immediately in front of it goes into a flange nut, you have the exact same thing going for you---except that the pushing and pulling screws are reversed in position.

Ralph Tremaine

As a belated aside, if you have not yet removed this sight from the gun (and if, in fact, the elevation screw goes into a flange nut), here's how to remove the sight: Remove the far forward screw. If, at this point, you can not simply lift the sight straight up and off, pull the assembly to the rear a bit---and lift it up. Given the presence of a flange nut, pulling the assembly to the rear a bit will clear the flange on the nut from its slot in the frame. Given the likelihood the far forward screw is not the least bit inclined to move, raise the elevation of the sight carrier until the sight clears its channel. Then secure the gun upright with the muzzle lower than the sight. (Remove the grips, and secure the grip frame in a vise.) Now pour some of your favorite screw "unsticker" juice into the sight channel, where it will run down toward the screw, and have direct access to the screw threads. The screw will become unstuck a whole lot quicker than if you pour the juice on the screw head---again and again and again---ad nauseum!! (Kroil is about the best "unsticker" juice there is.)