Smithbrother

Member

- Joined

- Sep 3, 2013

- Messages

- 143

- Reaction score

- 103

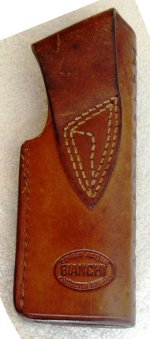

I've begun making holsters for my various revolvers just for fun. I started with remnant leather pieces to save money and made a few belt slides for my J Frames. Moved into new leather still within the learning curve of the craft, then began working with Buffalo leather. My latest creation is for my Model 69 that will accompany me to Alaska next summer. I call it the Okiotak. I've also completed a shoulder rig I call the Kenai, for the same weapon also in Buffalo. If there's any interest, I'll post the Kenai later. I call myself Two Feathers Leather, but so far have not made anything for public consumption.