Discussed this with a moderator as to where to put this thread and putting it here would be best.

I'll start off by stating the project was attempted just to see if it can be done, not to improve the loading/unloading of the cylinder. Moon clips are excellent and fast for that purpose.

The project was started about 5 years ago.

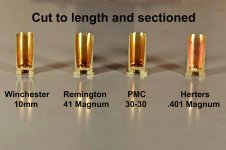

The first step was using 41 Remington Magnum brass. Ran one thru the 10mm sizing die. The solid part above the rim in the area of the primer flash hole was too 'solid' to size down. That area was 'machined' (using a file) down to match the sized down diameter of what was attained with the 10mm sizing die. Trimmed the length down to 10mm case length spec. That modified 41 Magnum case chambered well in the 610. The concern was having to machine multiple cases for actual load testing.

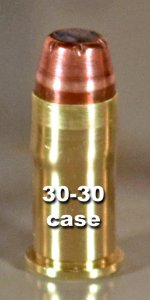

The next step was with a 30-30 case. The diameter above the rim was perfect for a 610. Used a tubing cutter at the area where the powder would normally be to rough length of a 10mm case. Trimmed it to length to 10mm case length spec. That modified 30-30 case chambered well in the 610. The concern was the thicker wall dimension of rifle brass and once a bullet was pressed into it, would it become too large in diameter to be chambered.

The project was put on hold for further investigation looking for something better.

I've got other posts to put in here, I just want to keep the pictures (many) relative to the text of the post.

I'll start off by stating the project was attempted just to see if it can be done, not to improve the loading/unloading of the cylinder. Moon clips are excellent and fast for that purpose.

The project was started about 5 years ago.

The first step was using 41 Remington Magnum brass. Ran one thru the 10mm sizing die. The solid part above the rim in the area of the primer flash hole was too 'solid' to size down. That area was 'machined' (using a file) down to match the sized down diameter of what was attained with the 10mm sizing die. Trimmed the length down to 10mm case length spec. That modified 41 Magnum case chambered well in the 610. The concern was having to machine multiple cases for actual load testing.

The next step was with a 30-30 case. The diameter above the rim was perfect for a 610. Used a tubing cutter at the area where the powder would normally be to rough length of a 10mm case. Trimmed it to length to 10mm case length spec. That modified 30-30 case chambered well in the 610. The concern was the thicker wall dimension of rifle brass and once a bullet was pressed into it, would it become too large in diameter to be chambered.

The project was put on hold for further investigation looking for something better.

I've got other posts to put in here, I just want to keep the pictures (many) relative to the text of the post.