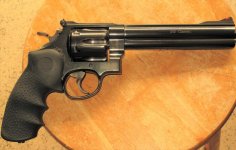

Just picked up a S&W M29-5 marked Classic with full 6 inch under lug barrel. Previous owner stated it is very hard to eject the empty cases with magnum shells. Will get it to the range and see what's up with that. For what I paid, I can put a few bucks into it and still be good

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me, Model 29-5 Classic!

- Thread starter Drifter Mike

- Start date

Register to hide this ad

A good cleaning might be in order before you shoot it. Very nice purchase, congrats on finding that one.

ironhead7544

Member

Nice find. Had one in stainless with non-fluted cylinder years ago.

You can have the chambers polished or do it yourself. Check at Brownell's for the equipment and oil.

You can have the chambers polished or do it yourself. Check at Brownell's for the equipment and oil.

OP

M29

Going to do a good deep cleaning on it before I shoot it and then will start off with 44 specials and see what happens

Going to do a good deep cleaning on it before I shoot it and then will start off with 44 specials and see what happens

75Vette

Member

Sweet! The 6 1/2" Classics balance out really well. Congrats on a great find.

OP

update

Update, did shoot 2 cylinder full with 44 spl ammo and NO issues. Did not shoot any mags through it but got to checking and the bullets seem a tight fit at the front of the cylinder. The bullets do not drop into the case as shown on my 686 357 and my 625 Mountain Gun in 45 LC. Is there a issue here?? see pictures, 357 and 45 LC both drop in to the case but the 44 has a small amount of bullet showing! Maybe I am over thinking this!

Update, did shoot 2 cylinder full with 44 spl ammo and NO issues. Did not shoot any mags through it but got to checking and the bullets seem a tight fit at the front of the cylinder. The bullets do not drop into the case as shown on my 686 357 and my 625 Mountain Gun in 45 LC. Is there a issue here?? see pictures, 357 and 45 LC both drop in to the case but the 44 has a small amount of bullet showing! Maybe I am over thinking this!

Attachments

DeplorabusUnum

Member

Ideally, for best accuracy, you want a bullet slightly larger than the cylinder like you seem to have, but only by one or two thousandths of an inch. You can get away with larger with lead bullets, but it looks like you're shooting FMJ. Any way you can measure your cylinders with pin gauges, and measure the width of your bullet? That would help answer your question.

BigMuddy

Member

Ideally, for best accuracy, you want a bullet slightly larger than the cylinder like you seem to have, but only by one or two thousandths of an inch. You can get away with larger with lead bullets, but it looks like you're shooting FMJ. Any way you can measure your cylinders with pin gauges, and measure the width of your bullet? That would help answer your question.

I have to disagree. Ideally you want a bullet that will push through the cylinder with minimal pressure, thus a bullet that is same as or VERY slightly under the size of the cylinder throats. You also want the throats nearly the same as bore diameter. If throats are tighter than bore diameter and bullet is larger than the throats, a lead bullet will swage down to throat size and be undersized for the bore. Accuracy suffers and leading usually occurs. Not as big of an issue with jacketed as they will “spring back” after being forced through the tight throats.

I am offering a possibility for the “hard to eject empties”. If the cylinder throats are too tight, pressures rise. In magnum loads the pressures may be high enough to cause sticky extraction. The fix, if this is the case, is to have the cylinder throats opened up to proper diameter. This is easily done.

Another possibility is dirty or rough chambers, another fairly easy fix.

Worse case possibility is oversized chambers allowing brass to expand too much, making them hard to eject. Doubt this is it, but only fix is new cylinder.

Since you had no problem with 44 Special I’m guessing it’s a pressure issue. All just guessing though without seeing the gun or the fired brass.

You can contact Fermin Garza and he can thoroughly check the cylinder for you. Fermin C Garza

Good luck with a great looking revolver.

Dan

Last edited:

Sweet acquisition!

I had an 8”. A little too long for my tastes. Don’t lose the rear sight tang. Very hard to replace.

I had an 8”. A little too long for my tastes. Don’t lose the rear sight tang. Very hard to replace.

John Patrick

Member

- Joined

- Dec 2, 2021

- Messages

- 1,575

- Reaction score

- 2,465

Nice, congrats.

DeplorabusUnum

Member

I have to disagree. Ideally you want a bullet that will push through the cylinder with minimal pressure, thus a bullet that is same as or VERY slightly under the size of the cylinder throats. You also want the throats nearly the same as bore diameter. If throats are tighter than bore diameter and bullet is larger than the throats, a lead bullet will swage down to throat size and be undersized for the bore. Accuracy suffers and leading usually occurs. Not as big of an issue with jacketed as they will “spring back” after being forced through the tight throats.

I am offering a possibility for the “hard to eject empties”. If the cylinder throats are too tight, pressures rise. In magnum loads the pressures may be high enough to cause sticky extraction. The fix, if this is the case, is to have the cylinder throats opened up to proper diameter. This is easily done.

Another possibility is dirty or rough chambers, another fairly easy fix.

Worse case possibility is oversized chambers allowing brass to expand too much, making them hard to eject. Doubt this is it, but only fix is new cylinder.

Since you had no problem with 44 Special I’m guessing it’s a pressure issue. All just guessing though without seeing the gun or the fired brass.

You can contact Fermin Garza and he can thoroughly check the cylinder for you. Fermin C Garza

Good luck with a great looking revolver.

Dan

I agree with everything you said, but my post was an answer to the OP's question in post #6 about bullet size relative to the throat, not the issue of sticky brass. I don't think sizing (cast) bullets slightly over throat diameter is rare or controversial. You are correct that if the throats are smaller than bore diameter, then you probably have a revolver that's not ever going to be very accurate. What I try to do is avoid sizing bullets under throat size. .001 to .002 over is most accurate in my revolvers. The OP appears to be shooting FMJ bullets, which is why I suggested measuring the bullets and the throats. And yes, I would slug the barrel as well. A throat size under bore diameter might possibly need to be re-bored for better accuracy, but the OP won't know until he measures everything.

Last edited:

BigMuddy

Member

Opening undersized cylinder throats is the fix rather than a re-bore of the barrel. I’ve done several 45’s. Haven’t had the issue with any of my 44’s but that doesn’t mean it isn’t possible.

Fermin is the man for truing up a cylinder. Send him the cylinder and he’ll measure and recommend the fix if needed. If everything is good, or you don’t want him to do the work, he returns the cylinder for the cost of postage. It’s worth the call to him.

Dan

Fermin is the man for truing up a cylinder. Send him the cylinder and he’ll measure and recommend the fix if needed. If everything is good, or you don’t want him to do the work, he returns the cylinder for the cost of postage. It’s worth the call to him.

Dan

Be careful with magnum rounds. You don't want a KB to happen. It's unlikely but still....

DeplorabusUnum

Member

Be careful with magnum rounds. You don't want a KB to happen. It's unlikely but still....

This^. Judging from picture #1 of post #6 your bullets are wider than your cylinder throats. I'd want to know how much bigger before attempting any magnum loads.

I've owned my 29-5 7in. classic 30 yrs cylinder throats are .4285 tight for sure jacketed bullets were their only concern, not cast, your gun most likely has a hard carbon build up in the cylinder from shooting 44 specials and does cause difficult ejection.

Similar threads

- Replies

- 4

- Views

- 228

- Replies

- 8

- Views

- 440

- Replies

- 2

- Views

- 589

- Replies

- 14

- Views

- 913

- Replies

- 7

- Views

- 451