SmithSwede

Member

Well, maybe not a full blown “design flaw,” but I found this to be an interesting little glitch.

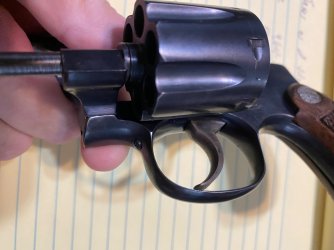

This is a 5 screw, S&W post war 1903 hand-ejector, regular I-frame. I think made in 1949.

The problem is that if the cylinder is in a certain position, one of the ejected cases can get caught in the notch of the thumb piece, preventing ejection. Obviously it doesn’t happen all the time, but I noticed it happening about 3 times in an an afternoon of plinking today.

I also had a Colt Pocket Positive with me today, and I confirmed that it is impossible for the same blockage to occur on the Colt.

I wonder if that is why S&W later switched to the flat style thumb piece.

This is a 5 screw, S&W post war 1903 hand-ejector, regular I-frame. I think made in 1949.

The problem is that if the cylinder is in a certain position, one of the ejected cases can get caught in the notch of the thumb piece, preventing ejection. Obviously it doesn’t happen all the time, but I noticed it happening about 3 times in an an afternoon of plinking today.

I also had a Colt Pocket Positive with me today, and I confirmed that it is impossible for the same blockage to occur on the Colt.

I wonder if that is why S&W later switched to the flat style thumb piece.