I've been reloading .357 Magnums for my Model 66-3 for a while now, I've always selected the lowest starting load data to ensure absolutely no overpressure or high pressure situations in my K frame.

Recently I've been using Hodgdon's RDC since it gives pressure readings for loads in PSI.

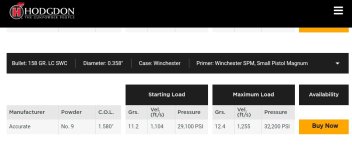

I've always used AA#9 with a 158 gr Zero Bullet Company JHP, cases around 1.287", with a loaded OAL of 1.580". Primers are CCI 550s, or CCI 500s, brass is from once fired Starline Sig .357 125 vcrowns. Load is 12.3-12.6 grs of AA#9 which according to Hodgdon's RDC which gives a starting of 12.4 grs at 31,500 psi, the max being 13.8 grs with 35,000 psi.

My issue is that even with a completely cleaned gun, and loads using standard and magnum primers, I'm getting fairly sticky extraction that's hard to push out using thumb pressure, don't have to use the power slap method to get the cases to extract, but still a bit troubling to me.

I've heard that chamber wall thickness can affect the stickiness of a case regardless of whether the load is close to max pressure, and even my downloads with 12.0 grs feel about as sticky as my standard pressure loads at 12.4 to 12.6 grs.

The question is, is that statement true? If I take my usual loads and put it into an N frame (with thicker chamber walls) would that decrease the stickiness of my loads?

Recently I've been using Hodgdon's RDC since it gives pressure readings for loads in PSI.

I've always used AA#9 with a 158 gr Zero Bullet Company JHP, cases around 1.287", with a loaded OAL of 1.580". Primers are CCI 550s, or CCI 500s, brass is from once fired Starline Sig .357 125 vcrowns. Load is 12.3-12.6 grs of AA#9 which according to Hodgdon's RDC which gives a starting of 12.4 grs at 31,500 psi, the max being 13.8 grs with 35,000 psi.

My issue is that even with a completely cleaned gun, and loads using standard and magnum primers, I'm getting fairly sticky extraction that's hard to push out using thumb pressure, don't have to use the power slap method to get the cases to extract, but still a bit troubling to me.

I've heard that chamber wall thickness can affect the stickiness of a case regardless of whether the load is close to max pressure, and even my downloads with 12.0 grs feel about as sticky as my standard pressure loads at 12.4 to 12.6 grs.

The question is, is that statement true? If I take my usual loads and put it into an N frame (with thicker chamber walls) would that decrease the stickiness of my loads?