shown50

Member

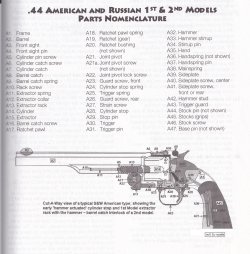

I bought this Model 3 American(Serial 4825) off GB the other night.

It doesn't have much, if any finish left.

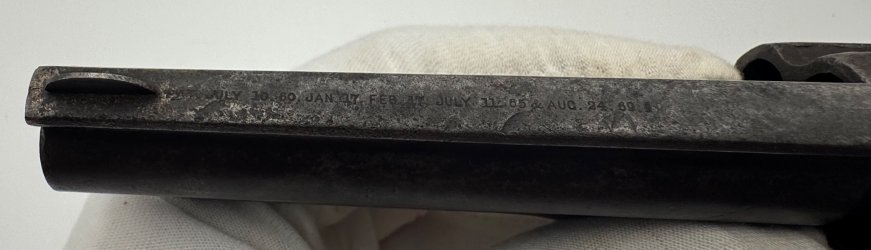

The barrel has been cut right before the Pat. JULY 10 60 date, and has a silver front sight.

All the assembly numbers(#34) match.

The stocks aren't numbered.

The extractor catch(not sure what it's called) has been broken off and/or filed down.

The action works and lock up is tight. The barrel to frame fit is still solid. The trigger pull is lighter and crisper than expected.

The ejector works empty(no ammo to test with).

This is my first time owning a Model 3 American and I've got a couple questions.

Did the assembly numbers start over for every batch of guns?

What length barrel would this have been cut from?

Are the side plate screws flat on these models?

Has anyone lettered a gun close to this serial, and did they have records for where it shipped to originally?

Any other thoughts or comments? I paid just under $1000 after fees+shipping.

It doesn't have much, if any finish left.

The barrel has been cut right before the Pat. JULY 10 60 date, and has a silver front sight.

All the assembly numbers(#34) match.

The stocks aren't numbered.

The extractor catch(not sure what it's called) has been broken off and/or filed down.

The action works and lock up is tight. The barrel to frame fit is still solid. The trigger pull is lighter and crisper than expected.

The ejector works empty(no ammo to test with).

This is my first time owning a Model 3 American and I've got a couple questions.

Did the assembly numbers start over for every batch of guns?

What length barrel would this have been cut from?

Are the side plate screws flat on these models?

Has anyone lettered a gun close to this serial, and did they have records for where it shipped to originally?

Any other thoughts or comments? I paid just under $1000 after fees+shipping.

Attachments

-

IMG_6064.jpeg884.8 KB · Views: 0

IMG_6064.jpeg884.8 KB · Views: 0 -

IMG_6080.jpeg998.4 KB · Views: 0

IMG_6080.jpeg998.4 KB · Views: 0 -

IMG_6074.jpeg1.4 MB · Views: 0

IMG_6074.jpeg1.4 MB · Views: 0 -

IMG_6075.jpeg1.2 MB · Views: 0

IMG_6075.jpeg1.2 MB · Views: 0 -

IMG_6076.jpeg814 KB · Views: 0

IMG_6076.jpeg814 KB · Views: 0 -

IMG_6071.jpeg599.7 KB · Views: 0

IMG_6071.jpeg599.7 KB · Views: 0 -

IMG_6072.jpeg840.1 KB · Views: 0

IMG_6072.jpeg840.1 KB · Views: 0 -

IMG_6073.jpeg742 KB · Views: 0

IMG_6073.jpeg742 KB · Views: 0 -

IMG_6069.jpeg450.3 KB · Views: 0

IMG_6069.jpeg450.3 KB · Views: 0 -

IMG_6070.jpeg1.1 MB · Views: 0

IMG_6070.jpeg1.1 MB · Views: 0 -

IMG_6062.jpeg1.1 MB · Views: 0

IMG_6062.jpeg1.1 MB · Views: 0 -

IMG_6068.jpeg1.5 MB · Views: 0

IMG_6068.jpeg1.5 MB · Views: 0 -

IMG_6067.jpeg1.1 MB · Views: 0

IMG_6067.jpeg1.1 MB · Views: 0 -

IMG_6063.jpeg954.9 KB · Views: 0

IMG_6063.jpeg954.9 KB · Views: 0