UPDATE - RANGE REPORT!!!

On January 16th I posted as seen below. The response I received from you guys was almost immediate. I received tips/suggestions/guidance all of which was very, very helpful.

Most people suspected the problem was excessive 'end shake' which was preventing the firing pin from contacting the rounds properly resulting in failure to fire.

Over the course of the first 24 hours I received guidance on how to measure and resolve the end shake. The measurements revealed about .013 of play in the cylinder. The solution appeared to be the installation of a very inexpensive shims to 'tighten up' the cylinder.

I ordered a set of shims and in the meantime, as was suggested, cleaned the internals thoroughly. The shims arrived yesterday and I installed them this morning.

I added two shims with thicknesses of .004 inside the cylinder and one .002 shim underneath the ejector star (a tip from 'BC38). This allowed me to reduce the end shake while minimizing additional gap between the cylinder and the barrel. The shims virtually eliminated the end shake and the cylinder felt rock-solid!

Once I had the gun reassembled I took off for a patch of Utah desert just a few miles from my house. I loaded the cylinder, held my breath, and squeezed the trigger - BANG!!!

Squeezing the trigger again and again - BANG, BANG, BANG, BANG, BANG!!!

I reloaded and emptied another cylinder without a single failure!!!

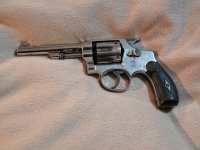

I now have a Nickel 1903 .32 Hand Ejector, born in 1909, with Mother of Pearl Grips that is fully functional!! More importantly is that's it's a gun that belonged to my Dad who passed away in 2004, and which as I mentioned in my first post, was written off as "too far gone" to repair by a local gunsmith!

I cannot begin to express my gratitude to everyone who responded and took the time to offer advice and encouragement , ESPECIALLY "BC38" who took the time to walk me through the entire process step-by-step. Without the help I received for you all, the gun would be a "paper weight with sentimental value" sitting in my safe instead of a piece of family history I can take out, shoot and enjoy!!!

who took the time to walk me through the entire process step-by-step. Without the help I received for you all, the gun would be a "paper weight with sentimental value" sitting in my safe instead of a piece of family history I can take out, shoot and enjoy!!!

I think my Dad would be proud that his gun has found a new life!!!

My next step is to cough up the $$$ to get an offical S&W Letter to see what I can learn of the revolvers history. I don't expect to learn anything earth-shattering but just know a little of when and where it came from will be worth the money to me.

Thank you all for everything you did for me!!! YOU GUYS ARE THE BEST!!!

Bob Neely a/k/a huskerbob

St. George, UT.

ORIGINAL POST

I have a .32 CTG I inherited when my Father passed. I don't know a lot about it other than the S/N which is 99851. It has MOP grips. It is in pretty rough shape. I would love to get it functional again. I have shown it to a gunsmith locally and he indicated the gun is probably "too far gone". That may well be the case. However, since it belonged to my Dad, I feel like I need to give it another try before giving up on it.

I have posted about the gun on this forum a few years ago but at that time I was trying to determine whether or not the gun had any value beyond sentimental.

What I'm hoping to learn this time is if they're might be a highly regarded gunsmith for this type of S&W revolver I might contact for a 'second opinion'

I will appreciate any guidance anyone can provide!!

Thanks!

On January 16th I posted as seen below. The response I received from you guys was almost immediate. I received tips/suggestions/guidance all of which was very, very helpful.

Most people suspected the problem was excessive 'end shake' which was preventing the firing pin from contacting the rounds properly resulting in failure to fire.

Over the course of the first 24 hours I received guidance on how to measure and resolve the end shake. The measurements revealed about .013 of play in the cylinder. The solution appeared to be the installation of a very inexpensive shims to 'tighten up' the cylinder.

I ordered a set of shims and in the meantime, as was suggested, cleaned the internals thoroughly. The shims arrived yesterday and I installed them this morning.

I added two shims with thicknesses of .004 inside the cylinder and one .002 shim underneath the ejector star (a tip from 'BC38). This allowed me to reduce the end shake while minimizing additional gap between the cylinder and the barrel. The shims virtually eliminated the end shake and the cylinder felt rock-solid!

Once I had the gun reassembled I took off for a patch of Utah desert just a few miles from my house. I loaded the cylinder, held my breath, and squeezed the trigger - BANG!!!

Squeezing the trigger again and again - BANG, BANG, BANG, BANG, BANG!!!

I reloaded and emptied another cylinder without a single failure!!!

I now have a Nickel 1903 .32 Hand Ejector, born in 1909, with Mother of Pearl Grips that is fully functional!! More importantly is that's it's a gun that belonged to my Dad who passed away in 2004, and which as I mentioned in my first post, was written off as "too far gone" to repair by a local gunsmith!

I cannot begin to express my gratitude to everyone who responded and took the time to offer advice and encouragement , ESPECIALLY "BC38"

I think my Dad would be proud that his gun has found a new life!!!

My next step is to cough up the $$$ to get an offical S&W Letter to see what I can learn of the revolvers history. I don't expect to learn anything earth-shattering but just know a little of when and where it came from will be worth the money to me.

Thank you all for everything you did for me!!! YOU GUYS ARE THE BEST!!!

Bob Neely a/k/a huskerbob

St. George, UT.

ORIGINAL POST

I have a .32 CTG I inherited when my Father passed. I don't know a lot about it other than the S/N which is 99851. It has MOP grips. It is in pretty rough shape. I would love to get it functional again. I have shown it to a gunsmith locally and he indicated the gun is probably "too far gone". That may well be the case. However, since it belonged to my Dad, I feel like I need to give it another try before giving up on it.

I have posted about the gun on this forum a few years ago but at that time I was trying to determine whether or not the gun had any value beyond sentimental.

What I'm hoping to learn this time is if they're might be a highly regarded gunsmith for this type of S&W revolver I might contact for a 'second opinion'

I will appreciate any guidance anyone can provide!!

Thanks!

Attachments

Last edited: