Blued Steel

Member

- Joined

- Apr 27, 2016

- Messages

- 14

- Reaction score

- 4

I have a 586 no dash. Trigger has been worked over by a s&w master. Trigger is phenomenally smooth in DA and super light in SA. Cocking the hammer is super smooth and trigger reset is butter smooth also.

I bought the gun second hand but the credentials for the trigger work came with the pistol as if it was a declaration of independence.

It says that if I experience light primer strikes I should turn the strain relief screw in 1/4 turn, however.I should use federal primers and ensure I am seating them correctly as that is likely the cause for light primer strikes. It also says I should send the pistol back to the guy once a year for servicing. The guy has since retired.

Being this was my first pistol and first time reloading, when I got light primer strikes(like...1 out of 50) I didnt immediately touch the screw. I started seating ALL of my CCI primers with more force on my lee tool. I've also started using win primers as well as cci. Since I started cranking the primers home more, I've never had an issue

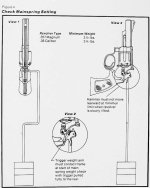

But... reason for this thread... is I havent ever come across a trigger job info peice where it ever reccomends touching the strain screw...and I've come across a lot of info mentioning the screw should ALWAYS be bottomed out.

Is it acceptable practice to do a professional trigger job and send the pistol out the door with a backed off strain relief screw?

Is a large part of my super special trigger job the fact that my strain screw is backed off? Now that the guys retired, should I take note of where it is currently so I can keep it exactly there? If not tight, will it move on its own?

I bought the gun second hand but the credentials for the trigger work came with the pistol as if it was a declaration of independence.

It says that if I experience light primer strikes I should turn the strain relief screw in 1/4 turn, however.I should use federal primers and ensure I am seating them correctly as that is likely the cause for light primer strikes. It also says I should send the pistol back to the guy once a year for servicing. The guy has since retired.

Being this was my first pistol and first time reloading, when I got light primer strikes(like...1 out of 50) I didnt immediately touch the screw. I started seating ALL of my CCI primers with more force on my lee tool. I've also started using win primers as well as cci. Since I started cranking the primers home more, I've never had an issue

But... reason for this thread... is I havent ever come across a trigger job info peice where it ever reccomends touching the strain screw...and I've come across a lot of info mentioning the screw should ALWAYS be bottomed out.

Is it acceptable practice to do a professional trigger job and send the pistol out the door with a backed off strain relief screw?

Is a large part of my super special trigger job the fact that my strain screw is backed off? Now that the guys retired, should I take note of where it is currently so I can keep it exactly there? If not tight, will it move on its own?