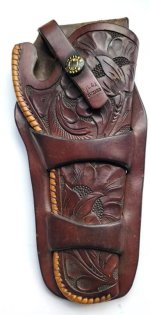

In a recent conversation with turnerriver we noted the use of a third type of snap buttons.

Probably during the war period,

given the shortage of brass, Heiser had resorted to a particular type of automatic button, this time in bronzed sheet metal with a characteristic 4-petal construction.

When dating gunleather we do tend to focus on the button vs the socket, as you're noticing now. The type you've shown is pre-war, the one we use today is wartime and into today.

Materials in the snaps are chosen for all kinds of reasons; stainless for maritime for example and originally was brass, to avoid rust from salt water. Ultimately the change to durable snaps was at War's beginning to get a better grip on such as tarpaulins on ship's decks.

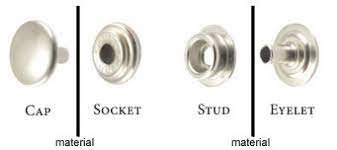

One can use a different metal on each of the four parts, for various reasons. Brass for the cap because the P.D. requires brass, but black steel on the other parts because they're cheaper. The eyelets come in different tube lengths depending on material thickness, the caps, too. The studs come with different 'platform' heights for the same reason.

If the maker chooses a cap or eyelet with a too-long barrel for the application, the barrel can either shear off when it is 'clinched' or pile up inside the mating part and interfere with the snap's function. They're a bloody nightmare even for little 'custom' makers.

Ultimately today's small makers don't use snapped straps because one can't count on them being set so well that they don't need replacing before they even leave the shop floor; the machines often shearing off the 'clinch' while the item is still 'work in process'.

Even modern 'security' holster came to rely on the snap as a last resort if the mechanisms of the holster failed, which then defeated the purpose of even having the mechanisms because the snaps can fail anyway. Safariland's security holsters show us just how hard they've battled this conflict.

The snap fastener types we will encounter in gunleather; the images are labelled: