|

|

|

|

02-07-2014, 03:13 PM

|

|

Member

|

|

|

Join Date: Mar 2008

Location: Paducah, KY

Posts: 261

Likes: 36

Liked 40 Times in 27 Posts

|

|

What types of bullets were used in .357 loads "back in the day"?

What types of bullets were used in .357 loads "back in the day"?

Looking to satisfy some curiousity here.

I know .357 is a product of the 30's but have read that functioning hollowpoints were only around starting in the 80's mainly. I know SuperVel was around from the 60's.

What bullets were used in the "old days"? Round nosed lead? SWC's? Those old conical metal piercing bullets? Just curious what the knowledgeable lawman or gun guy would have put in his .357 long before I was born.

__________________

Caretaker of a small herd.

|

|

The Following User Likes This Post:

|

|

02-07-2014, 03:18 PM

|

|

Member

|

|

|

Join Date: Mar 2005

Location: Oregon

Posts: 1,509

Likes: 442

Liked 1,309 Times in 477 Posts

|

|

158gr lead with some type of lube.

|

02-07-2014, 03:31 PM

|

|

Member

|

|

|

Join Date: Aug 2006

Location: Lexington, NC

Posts: 281

Likes: 28

Liked 165 Times in 76 Posts

|

|

I think they were originally loaded with a 158gr LSWC. I don't recall ever seeing it loaded with a round nose like the 38 spl was.

|

02-07-2014, 03:41 PM

|

|

Member

|

|

|

Join Date: Mar 2008

Location: Paducah, KY

Posts: 261

Likes: 36

Liked 40 Times in 27 Posts

|

|

Did they have any issues with pushing lead ammo that fast?

__________________

Caretaker of a small herd.

|

02-07-2014, 05:37 PM

|

|

Member

|

|

|

Join Date: Jan 2010

Posts: 620

Likes: 79

Liked 282 Times in 164 Posts

|

|

Primarily SWC and Metal Point/Matal Capped RN style bullets.

|

02-07-2014, 05:39 PM

|

|

Member

|

|

|

Join Date: Dec 2009

Location: South Texas & San Antonio

Posts: 35,561

Likes: 331

Liked 32,148 Times in 15,298 Posts

|

|

That is correct. The early Remington ammunition catalogs list both lead and metal-capped (metal point) 158 grain bullets @1510 ft/sec. I believe metal-capped bullets had just the nose covered. The bearing surface on the bore was lead. Western also listed a 158 grain metal piercing bullet and a 158 grain Luballoy Coated bullet, which was a FMJ.

Last edited by DWalt; 02-07-2014 at 06:04 PM.

|

02-07-2014, 05:41 PM

|

|

Member

|

|

|

Join Date: Mar 2008

Location: Paducah, KY

Posts: 261

Likes: 36

Liked 40 Times in 27 Posts

|

|

Anybody know where I can see pictures of some of this old stuff?

__________________

Caretaker of a small herd.

|

02-07-2014, 05:51 PM

|

|

Member

|

|

|

Join Date: Aug 2013

Location: Kansas City area

Posts: 890

Likes: 0

Liked 744 Times in 370 Posts

|

|

Quote:

Originally Posted by dsink

I think they were originally loaded with a 158gr LSWC. I don't recall ever seeing it loaded with a round nose like the 38 spl was.

|

I agree, I'm not saying a 158 gr. round nose was never made for the .357 but I've never seen one.

For general use today a hard cast 158-180 gr. is a pretty good load for the .357, especially for "woods carry".

|

02-07-2014, 06:15 PM

|

|

Member

|

|

|

Join Date: Dec 2009

Location: South Texas & San Antonio

Posts: 35,561

Likes: 331

Liked 32,148 Times in 15,298 Posts

|

|

The earlier .357 lead bullet cartridges I have seen all had the SWC bullet shape. I have not seen one with a round nose, but that does not mean that they weren't made. The bullets were deeply seated, with the "shelf" of the SWC bullet seated flush with the case mouth. The Remington catalog listing simply says "lead" for the bullet.

|

02-07-2014, 07:42 PM

|

|

SWCA Member

|

|

|

Join Date: Aug 2005

Posts: 7,981

Likes: 3,743

Liked 7,154 Times in 2,789 Posts

|

|

Quote:

Originally Posted by AJMBLAZER

Looking to satisfy some curiousity here.

I know .357 is a product of the 30's but have read that functioning hollowpoints were only around starting in the 80's mainly. I know SuperVel was around from the 60's.

What bullets were used in the "old days"? Round nosed lead? SWC's? Those old conical metal piercing bullets? Just curious what the knowledgeable lawman or gun guy would have put in his .357 long before I was born.

|

I think the originals were semi-wadcutter. Metal piercing were more like a pointed tip round.

|

02-07-2014, 09:43 PM

|

|

Member

|

|

|

Join Date: Jun 2013

Location: Texas

Posts: 105

Likes: 64

Liked 41 Times in 26 Posts

|

|

I'm not sure what bullets preceded the 125 grain JHP for defensive purposes, but it was probably the 158 grain previously described.

However, the famous "man stopper" is the 125 grain JHP.

Back in the 1960's, big bore fans asserted that .45 ACP 230 grain ball ammo would achieve 95% one shot stops. Subsequent research has shown that 230grain FMJ .45 ACP loads actually provide about 60-64% one shot stops and several smaller calibers using expanding bullets are more effective stoppers. The most effective of all self-defense handgun cartridges is the medium bore .357 Magnum with a 125 grain JHP bullet, which provides 93-97% stops. Those numbers are supported by a huge data base and several different researchers, working independently, have discovered essentially the same thing.

From an interesting read: Handgun Stopping Power

Just ignore that bit about the 45 ball ammo being less than a 100% fight stopper. Blasphemy I say!!

|

|

The Following 2 Users Like Post:

|

|

02-07-2014, 09:54 PM

|

|

Member

|

|

|

Join Date: Jun 2012

Location: Demon-class planet

Posts: 7,608

Likes: 30,348

Liked 8,738 Times in 3,896 Posts

|

|

Remington produced a 158gr JSP load which, for quite a while, was the only one of its kind. Winch's lead SWC had a much sharper shoulder than that of Rem. The Winch load was coated with a gold-colored copper wash, I believe it was called. Rem also produced a 158gr jacketed metal piercing load, but a poster on another thread said claims of metal piercing were too optimistic.

It took Norma to break the mold of the above loads by introducing their 158gr Magnum load; can't recall if JHP or JSP. Norma showed initiative by producing interesting .38 loads and the first .45ACP JHP.

|

|

The Following User Likes This Post:

|

|

02-07-2014, 10:18 PM

|

|

Member

|

|

|

Join Date: Feb 2003

Location: Retired to South Carolina

Posts: 870

Likes: 2,630

Liked 234 Times in 120 Posts

|

|

Quote:

Originally Posted by AJMBLAZER

Did they have any issues with pushing lead ammo that fast?

|

There are different kinds of lead, and lube.

The major factories, especially back then, were notorius for using whatever "wrong" combination of lead and lube - and they often leaded the barrels pretty bad. So bad, that even today, some folks still believe lead bullets are bad and mess up your barrel.

Well, I don't know that the major factories have stopped doing that.

But there are some smaller companies that do it right. And some individuals as well.

I'm still learning, but the folks who know what they are doing, don't have problems with leading their barrels.

__________________

July 4, 1776 not Jan 30, 1909

|

02-07-2014, 10:23 PM

|

|

Member

|

|

|

Join Date: Feb 2003

Location: Retired to South Carolina

Posts: 870

Likes: 2,630

Liked 234 Times in 120 Posts

|

|

Quote:

Originally Posted by AJMBLAZER

Just curious what the knowledgeable lawman or gun guy would have put in his .357 long before I was born.

|

Handloads were popular in some places, and apparently worked well.

There are books, articles, and forums discussing how it was done and how to do it now. Look for articles by the gun writers of the 1950's through the 1970's.

__________________

July 4, 1776 not Jan 30, 1909

|

02-07-2014, 11:02 PM

|

|

Member

|

|

|

Join Date: Sep 2011

Location: Central Texas

Posts: 1,283

Likes: 2,986

Liked 1,498 Times in 703 Posts

|

|

In the early 70's I vaguely recall what was referred to as a SJHP. That was what most wheel gunners carried on duty. I do recall that we qualified with .38 Special wadcutter and practiced mostly with the SWC ending with a cylinder or two of our .357 carry round. Department furnished the practice stuff and the officer had to buy his own duty loads.

hardcase60

__________________

You want me to do what?

|

|

The Following 2 Users Like Post:

|

|

02-08-2014, 01:13 AM

|

|

Member

|

|

|

Join Date: Oct 2006

Posts: 7,500

Likes: 2,391

Liked 6,702 Times in 3,310 Posts

|

|

The copper washed Winchester loads were called "Luballoy" and were pretty much a copy of their .22 lr high speed loads. Alas, the name was wishful thinking. 6 rounds and you couldn't see your rifling.

The metal piercing rounds were as described earlier, pointed metal cap on a lead bullet.

The Remington 158 SPs were loaded hot. I expect they were intended more as a hunting rounds than self defense.

Super Vel did indeed start the light bullet/high speed era in the mid-late 1960s. A friend got some of the first 125 gr JHP component bullets out (1970-71) and an ink-still-wet load data sheet (Hercules, now Alliant). They did expand, but very shortly Hercules came out with revised (downward, way downward) load data. Not really an issue, I'd looked at the data and decided that sticking the same powder charge I used in a .44 Magnum in a .357 case was not going to happen

BTW, lead hollowpoints were around even in the 1930s. There were even some interesting molds where you could cast your hollowpoint nose out of soft lead. This was then inserted into another mold that cast the bore riding body of the bullet out of much harder alloy while retaining the soft lead nose. But, you didn't see any of these from factories.

Last edited by WR Moore; 02-08-2014 at 01:17 AM.

|

|

The Following User Likes This Post:

|

|

02-08-2014, 02:30 AM

|

|

Member

|

|

|

Join Date: Dec 2009

Location: South Texas & San Antonio

Posts: 35,561

Likes: 331

Liked 32,148 Times in 15,298 Posts

|

|

Exactly what "Lubaloy" means is open to interpretation. Western got a patent in the early 1920s for a copper-zinc-tin alloy suitable for bullet jackets. Its main advantage was that it did not cause metal fouling of bores when bullets were fired at high velocity. Prior to that, jackets were made of cupro-nickel, and sometimes caused metal fouling in bores. Usually, Lubaloy bullet jackets were also given a copper wash for a better appearance. However, lead bullets which were given a copper wash were also called Lubaloy - so I guess the term was applied to any non-fouling bullets.

I have a 1930s era box of Western .38 Special ammunition, labeled as Lubaloy. Those bullets are definitely FMJ, not copper washed unjacketed lead.

Western's metal piercing bullets were of the capped type, using a heavy metal conical cap over a lead core. The bore riding surface was lead. It was the heavy metal (Lubaloy??) conical cap combined with the higher .357 velocity which enhanced its metal-penetrating performance. Remington's metal piercing bullets were different, as they were made from a hard zinc alloy.

Were copper-washed lead bullets used in loading .357 ammunition? I frankly don't know.

|

|

The Following User Likes This Post:

|

|

02-09-2014, 11:11 AM

|

|

Member

|

|

|

Join Date: Feb 2009

Location: Coastal NC

Posts: 2,946

Likes: 2,408

Liked 4,732 Times in 1,623 Posts

|

|

Having been given lots of old '60's era .357 mag ammo, mostly R-P, do recall the short, stubby ogive and shoulder seated below case mouth. The 158 gr. LSWC was about it except for the 'metal piercing' option for a long time.

A quick thumbnail check on the SWC's would tell you they were soft, almost surely swaged.

And yes, a few cylinders-full of them would turn your barrel into a smoothbore with the lead left behind. You were in for a long and aggravating cleaning session.

One thing from the old days that I don't miss.

__________________

Ret'd LEO

SWCA #2275

|

02-11-2014, 04:14 AM

|

|

Member

|

|

|

Join Date: Feb 2009

Location: Border

Posts: 426

Likes: 86

Liked 262 Times in 129 Posts

|

|

Quote:

Originally Posted by Old Corp

...And yes, a few cylinders-full of them would turn your barrel into a smoothbore with the lead left behind. You were in for a long and aggravating cleaning session.

One thing from the old days that I don't miss.

|

You know you're old when you here the word "Lewis" and the first thing coming to mind is Lewis Lead Remover. I learned that bronze wool was faster yet for getting lead out. Nonetheless, before then I spent a week, yes a WEEK, cleaning lead out of a barrel and off a cylinder face once. Several hours every night. The face of the cylinder looked like the skin of an orange!! Simply awful.

|

|

The Following 3 Users Like Post:

|

|

02-18-2014, 04:19 PM

|

|

US Veteran

|

|

|

Join Date: Sep 2002

Location: IL

Posts: 1,911

Likes: 1,062

Liked 3,787 Times in 995 Posts

|

|

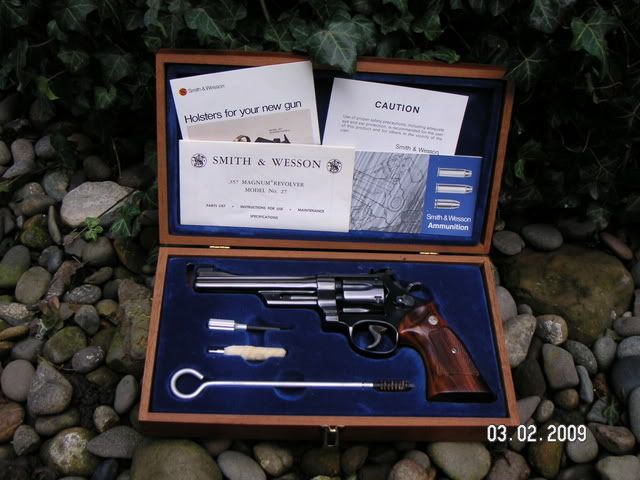

I just posted this pic on another thread:

Says metal point conical bullets on the back

__________________

My sgntr is mor thn 30 chrctrs

|

|

The Following 4 Users Like Post:

|

|

11-13-2015, 06:07 PM

|

|

Member

|

|

|

Join Date: Feb 2006

Location: MN

Posts: 60

Likes: 517

Liked 52 Times in 30 Posts

|

|

You can get some modern stuff like they used : https://www.underwoodammo.com/357-ma...-hollow-point/

Regards, Porkie

__________________

Least expected, you’re elected

|

11-13-2015, 07:04 PM

|

|

Member

|

|

|

Join Date: Jan 2011

Location: Mountains of Colorado

Posts: 2,998

Likes: 2,582

Liked 7,188 Times in 1,978 Posts

|

|

Quote:

Originally Posted by clang444

I just posted this pic on another thread:

Says metal point conical bullets on the back |

These bullets were loaded in 38 Special and 45 ACP as well. I sectioned a pulled metal piercing 357 bullet. It is essentially just a soft lead core with a thin metal jacket. Nothing exceptional.

|

11-13-2015, 07:10 PM

|

|

Member

|

|

|

Join Date: Nov 2010

Location: WINCHESTER, VIRGINIA

Posts: 3,355

Likes: 4,437

Liked 4,434 Times in 1,463 Posts

|

|

Quote:

Originally Posted by dsink

I think they were originally loaded with a 158gr LSWC. I don't recall ever seeing it loaded with a round nose like the 38 spl was.

|

Well Remington had them-- I had a box for years and fired them one day when I was out of the proper ammo for a 8" Python--  I won't tell you how long it took to get that bore clean--

|

11-13-2015, 11:01 PM

|

|

Member

|

|

|

Join Date: Oct 2008

Location: Denver, CO

Posts: 1,839

Likes: 178

Liked 1,015 Times in 503 Posts

|

|

I remember seeing some with the 158 grain lead round nose bullet. Mid to late 50s, I believe

|

11-14-2015, 09:19 PM

|

|

Member

|

|

|

Join Date: Sep 2015

Location: Texas

Posts: 497

Likes: 82

Liked 682 Times in 236 Posts

|

|

I got into Law Enforcement in 1977. Most guys that carried a .357 had some kind of LSWC. There were a few JHP but they were expense and didn't expand unless fired into concrete. The JHP bullet was simply a FMJ with a HP bored into it. There were Super Vels but they were really expensive. I bought one box for my 1911 .45, I used'm as long as I could then went to a 200 gr LSWC. I just didn't have the income to afford more. BTW, lead in the barrel was no problem. You covered the forcing cone with one finger, poured mercury in the barrel, covered the muzzle end of the barrel with another finger and tilted it back and forth a few times. A cloth patch pushed all the lead out and you could use that mercury over and over. There were guys carrying .38s, I only remember the LRN being used in them. The guys with 9 mm all carried the RNFMJ. I was carrying a M28 in my first gunfight. I loaded my own ammo because I knew the factory stuff wasn't the best. I found a Sierra Bullet, I think it was, that had a 3/4 jacket, with a very soft SWCHP front end. It worked very well. In the late '80s we were discouraged from carrying our own loads but there was some JHP ammo available by then. From '77 until '91 I provided my gun, ammo and leather gear. We then got the low bid gun, leather and ammo. Some departments issued better stuff and many didn't. Until the late 80s at least 50% of the guys carried a shotgun, their own, with buckshot, whatever was on sale.

|

|

The Following 3 Users Like Post:

|

|

11-14-2015, 11:00 PM

|

|

Member

|

|

|

Join Date: Apr 2003

Location: Rochester, NH USA

Posts: 4,174

Likes: 1,816

Liked 5,290 Times in 1,833 Posts

|

|

"I was carrying a M28 in my first gunfight. I loaded my own ammo because I knew the factory stuff wasn't the best. I found a Sierra Bullet, I think it was, that had a 3/4 jacket, with a very soft SWCHP front end. It worked very well."

Those were the Speer bullets... .357s came in 146 grain HP and 160 soft point, .41s in 200 HP and 220 SP and .44s in a 225 HP and 240 SP.

If one is looking for commercial loads that were available "back then", just find a SHOOTERS BIBLE of the era you are looking for. They have a list of all that was available and many pictures.

Bob

|

|

The Following 4 Users Like Post:

|

|

11-15-2015, 03:43 PM

|

|

Member

|

|

|

Join Date: Sep 2015

Location: Texas

Posts: 497

Likes: 82

Liked 682 Times in 236 Posts

|

|

I do believe you are right Bob. It's has been awhile. I shot a bad guy through the meaty part of his upper right arm when he pointed his gun at me. My round pushed a half dollar size hole through his arm and left meat hanging out the back. I liked it a lot.

|

|

The Following 2 Users Like Post:

|

|

11-15-2015, 07:51 PM

|

|

SWCA Member

Absent Comrade

|

|

|

Join Date: May 2006

Location: South Florida, USA

Posts: 2,763

Likes: 7,970

Liked 4,681 Times in 1,607 Posts

|

|

Did the original .357 Cartridge have a large primer pocket ?

__________________

ANTIQUESMITHS

LM1300 SWHF425

Last edited by model3sw; 11-15-2015 at 07:54 PM.

|

11-15-2015, 08:21 PM

|

|

Member

|

|

|

Join Date: May 2015

Location: Middle Georgia

Posts: 2,331

Likes: 4,550

Liked 5,577 Times in 1,319 Posts

|

|

That metal penetrating round wasn't bad. We used to go out to any junkyard (back when we had junkyards) and shoot old cars and freezers with them. . .used 38 specials which was all we had. The penetration was really impressive. They were kind of like a baby high-powered rifle hard ball load. They have been outlawed since I don't know when. Over 20 years ago my friends at ATF told me they had been illegal for a long time. That's back when they were all worried about the Teflon bullets.

__________________

Dr. B

|

|

The Following User Likes This Post:

|

|

11-16-2015, 12:20 PM

|

|

Member

|

|

|

Join Date: Apr 2003

Location: Rochester, NH USA

Posts: 4,174

Likes: 1,816

Liked 5,290 Times in 1,833 Posts

|

|

Quote:

Originally Posted by shotgun693

I do believe you are right Bob. It's has been awhile. I shot a bad guy through the meaty part of his upper right arm when he pointed his gun at me. My round pushed a half dollar size hole through his arm and left meat hanging out the back. I liked it a lot.

|

I have shot those bullets into test traps of both water and wood and they are very interesting. The bullets don't "expand"...the nose kinda "melts" off and this little copper jacketed ashcan just keeps going... I once shot a BBQ propane tank using a 8 3/8" 57. The first load was a 255 Cast Performance hard cast that was going in the 1400s...it put a big dent in the bottle. A 200 HP backed by 23 grains of H110 punched a hole in the tank and dented the backside...

Was visiting Allan Jones who was the editor of their reloading manual and an old friend from Dallas in 2003. He showed me the machine that line of bullets had been made on since the 1960s. He said the machine was not going to last much longer and when it could no longer be repaired the line was going to be dropped...and sure enough a few years later they were gone...I miss that bullet...

Bob

Last edited by SuperMan; 11-16-2015 at 12:26 PM.

|

|

The Following 2 Users Like Post:

|

|

11-16-2015, 01:03 PM

|

|

Member

|

|

|

Join Date: Mar 2012

Location: central Illinois

Posts: 111

Likes: 292

Liked 110 Times in 36 Posts

|

|

I wasn't in LE and never had to use those 146 gr Speers in anger, but from an old 3-screw Blackhawk with 11/2 power scope they were AWSOME on coyotes and the bigger heavier "coy-dogs" we had to help get rid of around the farms and small town dumps west of Indianapolis. If I could buy them now I might start hand loading again.

|

|

The Following User Likes This Post:

|

|

11-16-2015, 01:42 PM

|

|

Member

|

|

|

Join Date: Nov 2011

Location: Baton Rouge, La.

Posts: 7,488

Likes: 9,010

Liked 9,268 Times in 4,125 Posts

|

|

Soft , swaged lead, semi-wadcutter, 158 grain , with a thin coating of dry lube .

They would lead the bore in no time. Too many fps and too soft an alloy, that gave the first 357 magnums a bad reputation.

Hard cast , gas checked and deeper lube grooves helped. Jacketed bullets cured the leading problem.

Later Super-Vel came out with those neat jacketed hollow points and we haven't looked back .

Gary

Last edited by gwpercle; 11-16-2015 at 01:45 PM.

|

11-16-2015, 06:39 PM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,358 Times in 5,550 Posts

|

|

I'm no Leo, but my most accurate load was the Speer 140gr jhp. Pin point accuracy out to small rocks on the berm at 100yds. Python 6" barrel.

Wasn't the s&w ammo in 357mag, 125gr jhp 1597 f p s? Rated at?

Last edited by BigBill; 11-16-2015 at 06:41 PM.

|

11-16-2015, 08:26 PM

|

|

Member

|

|

|

Join Date: Jun 2012

Location: Demon-class planet

Posts: 7,608

Likes: 30,348

Liked 8,738 Times in 3,896 Posts

|

|

Back in the 70s and 80s, LE administrators were absolutely terrified of SJHP loads. Those were the days of the antis braying about dum-dum bullets. On one job, we were restricted to 158 grain lead bullets in .38 Special. Obviously, they expected us to use RNL. I just never told anyone, but the FBI/Chicago LHP load I used was a 158 grain lead bullet...

Kaaskop49

Shield #5103

|

11-16-2015, 11:01 PM

|

|

Member

|

|

|

Join Date: Nov 2013

Location: SW PA

Posts: 378

Likes: 279

Liked 500 Times in 216 Posts

|

|

Back in the 80's & early 90's, prior to the advent of the semi-automatics, I carried a Smith & Wesson Model 686 4 inch. One of the most effective anti-personnel rounds at the time the the Federal Cartridge Corporation 125 grain jacketed hollow point. I believe that Federal may have loaded the Sierra 125 grain jacketed hollow cavity. I have no scientific evidence, but recall articles in LE periodicals that, with proper placement, this was a very effective fight stopper. It came with a cost however. There was tremendous blast and, with sustained use, flame-cutting to the top strap just above the forcing cone. No such thing as a free lunch.

I carried this cartridge for many years. Fortunately I never had to employ this on two-legged animals, only those with four. We got, and still get, many calls to euthanize deer. Very rarely did I ever have to shoot a deer more than once.

Nothing scientific here, just my observations. I never felt out-gunned with this weapon/cartridge combination. I still have boxes of this ammunition and shoot it occasionally. With practice there is no problem shooting quickly and accurately.

jm2c.

Joe

|

|

The Following User Likes This Post:

|

|

11-17-2015, 09:49 AM

|

|

Member

|

|

|

Join Date: Apr 2003

Location: Rochester, NH USA

Posts: 4,174

Likes: 1,816

Liked 5,290 Times in 1,833 Posts

|

|

Quote:

Originally Posted by kaaskop49

Back in the 70s and 80s, LE administrators were absolutely terrified of SJHP loads. Those were the days of the antis braying about dum-dum bullets. On one job, we were restricted to 158 grain lead bullets in .38 Special. Obviously, they expected us to use RNL. I just never told anyone, but the FBI/Chicago LHP load I used was a 158 grain lead bullet...

Kaaskop49

Shield #5103

|

..you should have come to Texas...they didn't care what we shot people with as long as it got the job done...

|

|

The Following 5 Users Like Post:

|

|

11-18-2015, 01:17 AM

|

|

Member

|

|

|

Join Date: Feb 2005

Location: Corvallis, Oregon

Posts: 688

Likes: 3,774

Liked 866 Times in 365 Posts

|

|

My wife was a Border Patrol Agent in the mid-80's. While she carried .38 Special Treasury loads in her older Security-Six, you could get a box of .357s if you wanted. She got a box to try and it was Federal 158 grain JSP. We both tried them in her Ruger with the small wooden grips: ouch! Some of the agents at her station had the newer Security-Sixes in stainless with a heavier barrel and Pachmyer Presentation grips and I imagine those would have handled the magnums a lot better.

|

|

The Following User Likes This Post:

|

|

11-18-2015, 02:26 AM

|

|

Member

|

|

|

Join Date: Mar 2012

Location: Upstate, SC

Posts: 2,389

Likes: 3,785

Liked 5,944 Times in 1,844 Posts

|

|

Amongst knowledgeable 357 shooters, one of the most respected cast bullet designs was the Lyman 358156. Also known as the Thompson bullet, named for it's designer, it is a gas check SWC that can weight between 155 and 160 grains depending on alloy and when the mold was made. One of the unique features is a pair of crimp grooves allowing you to use it in 357 or 38 brass and still achieve the same overall length. I also seem to recall seeing a hollow point version, but I can't remember if that was a special order or someone's custom work.

In any case, assuming your cylinder throats and groove diameter were a good match, and bullets cast to throat diameter or .001" over, you could count on fine long range accuracy and fairly flat trajectory. The gas check really helped, which is noteworthy since many times it doesn't help too much. Cast hard, it is a real penetrator and fine hunting bullet. Loaded down a bit from full loads, and cast a little softer (1:16 tin lead) and it is a fine service load.

It had been my observation that the JHP/JSP trend really started to catch on around the same time that Colt and S&W started letting guns out that were out of spec (timing issues, excessive variations in cylinder throats, etc.)

Then again, I'm one of those guys that is cast bullet biased!

Best regards,

Jim

|

|

The Following User Likes This Post:

|

|

11-18-2015, 01:33 PM

|

|

Member

|

|

|

Join Date: Jun 2012

Location: Demon-class planet

Posts: 7,608

Likes: 30,348

Liked 8,738 Times in 3,896 Posts

|

|

Quote:

Originally Posted by Darkenfast

My wife was a Border Patrol Agent in the mid-80's. While she carried .38 Special Treasury loads in her older Security-Six, you could get a box of .357s if you wanted. She got a box to try and it was Federal 158 grain JSP. We both tried them in her Ruger with the small wooden grips: ouch! Some of the agents at her station had the newer Security-Sixes in stainless with a heavier barrel and Pachmyer Presentation grips and I imagine those would have handled the magnums a lot better.

|

Grips can have 2 "faces:" one when installed, and a 2nd when fired. The Colt Mk V .357 snub had a nice-feeling service-style wood grip that turned into a beast when fired with Mag loads. I found a pair of Pach Grippers, but they made the gun as heavy as a 4". Adios, muchacho.

Kaaskop49

Shield #5103

|

11-19-2015, 01:35 PM

|

|

SWCA Member

|

|

|

Join Date: May 2014

Posts: 9

Likes: 0

Liked 8 Times in 2 Posts

|

|

At least some of the original 357 ammo used large primers. This is a partial box I was given in the 70's. Fired a couple in a Model 28 back then and I remember they had more recoil than commercial ammo of the time.

|

|

The Following 5 Users Like Post:

|

|

11-27-2015, 03:26 PM

|

|

Member

|

|

|

Join Date: Jan 2008

Location: central ohio

Posts: 1,393

Likes: 957

Liked 835 Times in 493 Posts

|

|

Groo here

I think the 38-44 high speed also used a large primer

|

11-27-2015, 04:40 PM

|

|

Member

|

|

|

Join Date: Nov 2014

Location: Silicon Valley in Califor

Posts: 406

Likes: 96

Liked 538 Times in 230 Posts

|

|

I remember having Super Vel .357s in my Colt Trooper when I was a Reserve Deputy back in the 1970s. I will have to look around and see if I still have a box to take a photo of.

__________________

RudyN

NRA Patron Life Member

|

11-27-2015, 10:49 PM

|

|

Member

|

|

|

Join Date: Oct 2015

Location: Southern NJ

Posts: 4,788

Likes: 20,018

Liked 4,297 Times in 1,917 Posts

|

|

Quote:

Originally Posted by JFthunder

I wasn't in LE and never had to use those 146 gr Speers in anger, but from an old 3-screw Blackhawk with 11/2 power scope they were AWSOME on coyotes and the bigger heavier "coy-dogs" we had to help get rid of around the farms and small town dumps west of Indianapolis. If I could buy them now I might start hand loading again.

|

I used those old Speer 146gr 1/2 jacket HPSWC bullets in my S&W Model 27 with 8.375" barrel when I shot IHMSA metallic silhouette. It was VERY effective on the 200 meter rams!

While the early 357s were loaded with 158 SWC bullets, I think that you will find that many of those bullets wore gas checks on the heel of the bullets to minimize leading.

__________________

Judge control not gun control!

|

11-27-2015, 11:14 PM

|

|

Member

|

|

|

Join Date: Feb 2007

Location: Oregon

Posts: 2,403

Likes: 4,558

Liked 2,141 Times in 770 Posts

|

|

Great thread!

Great thread!

I am learning a few things I didn't know, and I do appreciate the personal experiences shared. Kudos All!

A little off topic, but the popular loads back when I was getting into shooting were the 125gr semi-jacketed soft point rounds. I wasn't reloading then, nor shooting much .357, so the brands and velocities are hazy, but I seem to recall Remington (or Federal???) being pretty darn hot. I was really impressed with a piece of 1/4" steel plate that a buddy had with a nice .357 hole in it, big crater too. He just said it was "a kind of hot load"....yeah, right!

When I picked this M27 at the shop (GB sale) I found all the paperwork in the case under the insert (seller apparently never knew it was in there). The shop "assistants" were expressing great disbelief over some of the loads in the helpful hints brochure (I think that was it, CRS!) - some of the lighter grain loadings were listed at 1500-1600 fps or more! I should probably dig it out and scan it sometime... but whatever, there were many who regarded the .357 as a rifle in the shape of a handgun! Thank you Elmer Keith, Phillip B. Sharpe, and Colonel D. B. Wesson!

__________________

ΜΟΛΩΝ ΛΑΒΕ

|

|

The Following 2 Users Like Post:

|

|

11-28-2015, 04:13 AM

|

|

Member

|

|

|

Join Date: Apr 2013

Posts: 2,060

Likes: 2

Liked 1,595 Times in 888 Posts

|

|

If "Older Days" means 1930s -50s , as noted , the store bought options were swaged 158 swc, sometimes with gas check, some times copper washed, or the metal capped " metal piercing "..In No Second Place Winner , Bill Jordan wrote of carrying .38Spl in towns, and .357 out in the brush ( pre- expanding era ). Skeeter Skelton wrote of frequently using .38-44 loads in his .357 guns ( again in pre- expanding era ).

A gun savy lawman in the day would have carried handloads. Kieth or Thompson or Sharpe SWC probably wouldn't expanand either, but : have sharper shoulders & larger meplats, less bbl leading, could be tailored to desired vel level ( aka desired level of recoil/ control).

For that matter , if not specifically required to use a .38/.357 , a gun savy lawman would also likely to choose a .44Spl .

|

|

The Following 3 Users Like Post:

|

|

11-30-2015, 06:25 PM

|

|

Member

|

|

|

Join Date: Feb 2003

Location: Retired to South Carolina

Posts: 870

Likes: 2,630

Liked 234 Times in 120 Posts

|

|

Casting and hand loading really bring out what this round can do. Some of the molds were designed to maximize what can be done using (150 gr cast and 38Special brass) the shorter cylindered revolvers.

Quote:

Originally Posted by 2hawk

The shop "assistants" were expressing great disbelief over some of the loads in the helpful hints brochure (I think that was it, CRS!) - some of the lighter grain loadings were listed at 1500-1600 fps or more! I should probably dig it out and scan it sometime... but whatever, there were many who regarded the .357 as a rifle in the shape of a handgun! Thank you Elmer Keith, Phillip B. Sharpe, and Colonel D. B. Wesson!

|

A lot of first hand experience and information has been lost in the last several decades as folks have passed away and trends have shifted.

The 357Magnum is one effective, and flexible, round.

For more fun, try it in a 16" barreled carbine sometime - 180 gr handloads with Lil Gun (out of the 16" barrel) approach or surpass some original 190 gr loadings for the 30-30 (out of a 24" or so rifle barrel).....

There is a reason the "modern" 125 gr 357Sig round works so well on the street - (paper ballistics do not tell the whole story (same as we find for the large bore revolver rounds)).

__________________

July 4, 1776 not Jan 30, 1909

Last edited by Poohgyrr; 11-30-2015 at 06:32 PM.

|

|

The Following User Likes This Post:

|

|

11-30-2015, 06:53 PM

|

|

US Veteran

|

|

|

Join Date: Feb 2008

Location: The Bluegrass state

Posts: 1,458

Likes: 1,116

Liked 1,948 Times in 618 Posts

|

|

I have seen and shot metal point bullets in .357 magnum many years ago.

I bought these a few years ago, didn't know they made them for reloading purposes.

terry

|

|

The Following User Likes This Post:

|

|

12-01-2015, 01:00 AM

|

|

Member

|

|

|

Join Date: Sep 2007

Location: Idaho

Posts: 679

Likes: 1,041

Liked 811 Times in 271 Posts

|

|

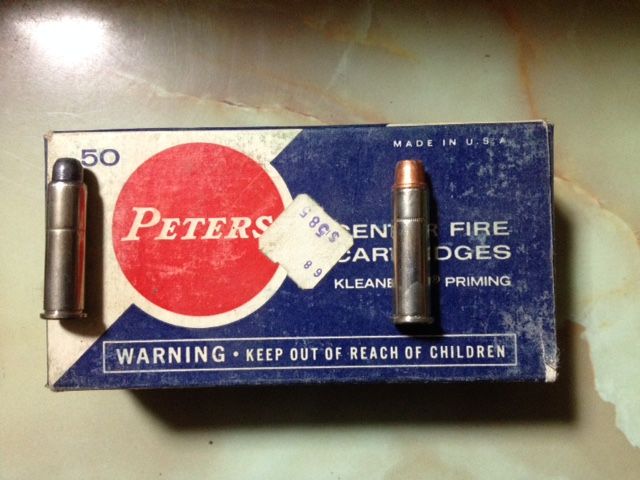

These two rounds aren't from 1935, but they are over 50 years old, which is close to "back in the day." The one on the left is a Peter's "158 grain lead" (the identical round also came in a Remington box) and the one on the left is a Winchester-Western Lubaloy. Yes, both will lead the barrel nicely.

|

12-07-2015, 02:13 PM

|

|

Member

|

|

|

Join Date: Jan 2015

Location: Southeast USA

Posts: 116

Likes: 94

Liked 94 Times in 45 Posts

|

|

Found these in my archive. Would you suppose that they would do well in a J frame .357? They are a little old & probably not as powerful as when new. Not as expensive as you would think.

|

|

The Following 2 Users Like Post:

|

|

12-08-2015, 06:11 AM

|

|

SWCA Member

Absent Comrade

|

|

|

Join Date: Nov 2002

Location: SLC, Utah

Posts: 4,863

Likes: 739

Liked 3,282 Times in 1,284 Posts

|

|

An old neighbor, Joe E., retired from Immigration & Naturalization in about 1982 or 83. He had worked in the U. S. Border Patrol in Texas and Arizona before that. Great old guy, great wife, Lois. They were retiring to land they owned in Tennessee. He left me with some odds and ends to shoot up. He said the oldest was their original duty ammo (from his era, probably mid-to-late 1950's) Western brand .357 Magnum ammo. It was 158 grain SWC with a copper wash. Cases were nickel. He had been shooting them in his 2-1/2-inch Model 19 S&W. He gave me about 75-80 of them. I shot all but 2 or 3. They leaded my 6-inch Model 28 so badly the rifling was completely covered. I pulled the bullet from one of the last, unfired cartridges with an inertia hammer. The bullet was plain-based, swaged, soft lead. As soft as the Speer and Hornaday swaged bullets. Copper wash covered the entire bullet but made it no harder. They squished as easily with a pair of pliers as did a Speer swaged bullet. My cast bullets, mostly heat-treated cast lead alloy (mostly wheel weights with some plumber tin) were far harder .

He told me that all the agents complained about the lead magnums. Took a lot of work to clean their guns after qualifying.They were very powerful but really dirty and the agents were all very happy to get jacketed hollowpoints later.

I showed him how to clean his chamber and bore with some Big .45's Frontier metal scrub pad threads wrapped around the appropriate bore brush.

Last edited by BUFF; 12-08-2015 at 06:20 AM.

|

|

The Following User Likes This Post:

|

|

|

|

Posting Rules

Posting Rules

|

|

|

|

|