Ralph, work with me. A lot of newbies read these posts. If I say no wool, they will undoubtedly not listen. I figure the OP may seek a little more advice. I hate to see these old survivors ruined by amateurs.

Okay, here's a word or two (or 6 or 8) about Steel Wool: Steel Wool removes rust. Bluing is rust (Black Oxide by name). (How's that, seven words?)

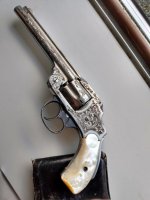

Yeah, I know this is a nickel gun. What I don't know is whether nickel is tougher than steel. I'd be betting it isn't, but I'm not going to be experimenting with nickel on a gun.

A few more words about bluing: The process is known as "controlled corrosion". That, in and of itself, should tell you all you need to know---about the steel wool topic.

As to pretty much any other topic that has anything to do with guns (S&W in particular), if you hang around here very long, you're going to be exposed to a whole lot of very hip dudes who've been there and done that, and you're going to lose your amateur status pretty damn quick! Then there's a select few---those I refer to as STUDENTS. They're a cut above the "hip dudes"-----WICKED SMART!! They may not be wicked smart about any and everything (and they'll be the first to tell you that), but if/when you get into the topics where they're STUDENTS, watch out---and when they talk, any and everybody who has the brains God gave a peanut, LISTENS! And they listen in AWE! They're easy to spot---anytime you're absolutely dumbfounded by what they're saying, and you're wondering how in the world can anybody know that much, THAT'S one of the STUDENTS!!

And it's all free for nothing-----unless you turn loose of some of your cash, and make a contribution to keep this hive going and growing. I'm pretty sure there's a sign somewhere here that says DONATIONS-----or CONTRIBUTIONS---or some such. Find it. Read it. There are some benefits to being a contributor---above and beyond just being a good guy and helping to keep all this rolling along.

Ralph Tremaine

It took awhile to come to mind, and it's not about steel wool; but bluing. "Bluing is not something applied to the surface of a gun----it IS the surface of the gun." And yet another: That which is "controlled" in the process of bluing, "controlled corrosion", are the chemicals employed (the corrosive agents), the temperatures at which they're employed, and the time for which they're employed. (A county Sheriff once approached a wizard of a gunsmith of my acquaintance. The Sheriff had a commercial grade Thompson Sub Machine Gun he wanted to have refinished (the one with the cooling fins on the barrel)---and he wanted "something special". He got it! Step One was the polishing---absolute perfection. Then the "controlled corrosion": It was controlled for a very brief period of time, and the end result was much like looking into a perfect light blue ice cube. The Sheriff was a happy camper!)