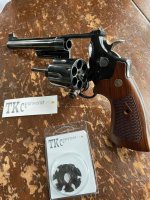

Figured I'd start a new thread on this as I've learned some things through experimentation. I've been shooting my 625-8 JM revolver quite a bit and have had some failure to fire issues with different configs. I picked it up used late last year and it had a very light DA trigger pull. Turns out the previous owner had backed off the strain screw. Light strike problem number one..... After I tightened it up I lost my buttery smooth and light trigger pull and that just wouldn't do. I have had good luck with Wilson spring kits in a couple other revolvers so I gave it a shot in this 625. No dice. Several light strikes on my next range trip. I added a Power Custom extended firing pin. When I swapped it out some "gunk" came out of the firing pin channel so I figured it would all be cool now. No dice. The other variable I had was the use of the 625 RIMZ polymer moon clips. For this last weekend I'd swapped back to the factory hammer spring. It didn't play nice with the Wilson 14lb trigger return spring. A Wolff 14lb spring worked fine so that's what I stuck with.

The 625 RIMZ polymer moon clips introduce some "play" into the situation. With the factory hammer spring and the Power Custom extended firing pin I had no issues setting off primers in single action. I had two failures to fire of the 24 rounds I shot double action. Switching to steel moon clips I had zero issues.

A quote from the RIMZ website:

The RIMZ 625 moon clip is made out of a more flexible Polymer material ( compared to the RIMZ 25 moon clip ) and is the easiest moon clip to load and unload, and is for RANGE use ONLY. The RIMZ 625 moon clip will also fit all the revolvers listed on this website( see RIMZ 25) EXCEPT the S&W 625-3 and older.

I really like the plastic moon clips as they do make it super easy to load and unload clips, but I just need to remember that they are not 100%.

My "final configuration" for the 625-8 JM is a stock hammer spring, Wolff 14lb trigger return spring, and the Power Custom extended firing pin. With steel clips I'm 100%, and I have a nice and smooth double action. I need to get a good gauge and see what the trigger pull is SA/DA.

For the record I've had zero ignition issues with the Wilson spring kits for the K/L/N on anything that wasn't 45acp. My 624-ND and my 27-2 both are running Wilson hammer springs and return springs with zero issues. 45acp guns apparently need the heavier hammer springs.

The 625 RIMZ polymer moon clips introduce some "play" into the situation. With the factory hammer spring and the Power Custom extended firing pin I had no issues setting off primers in single action. I had two failures to fire of the 24 rounds I shot double action. Switching to steel moon clips I had zero issues.

A quote from the RIMZ website:

The RIMZ 625 moon clip is made out of a more flexible Polymer material ( compared to the RIMZ 25 moon clip ) and is the easiest moon clip to load and unload, and is for RANGE use ONLY. The RIMZ 625 moon clip will also fit all the revolvers listed on this website( see RIMZ 25) EXCEPT the S&W 625-3 and older.

I really like the plastic moon clips as they do make it super easy to load and unload clips, but I just need to remember that they are not 100%.

My "final configuration" for the 625-8 JM is a stock hammer spring, Wolff 14lb trigger return spring, and the Power Custom extended firing pin. With steel clips I'm 100%, and I have a nice and smooth double action. I need to get a good gauge and see what the trigger pull is SA/DA.

For the record I've had zero ignition issues with the Wilson spring kits for the K/L/N on anything that wasn't 45acp. My 624-ND and my 27-2 both are running Wilson hammer springs and return springs with zero issues. 45acp guns apparently need the heavier hammer springs.