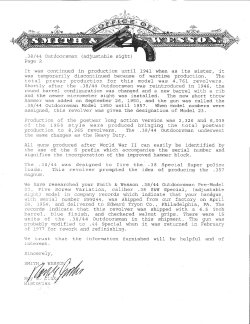

I have a question for the S&W N-frame collectors and historians on the forum. Did the Smith & Wesson factory make a habit converting Outdoorsman revolvers to 1950 Targets during the 1970's? I purchased this revolver 2006. It came with the factory letter and the six-inch barrel installed. The four-inch barrel packed separately. I shot with the six-inch for a couple of weeks and then installed the four-inch as I already had a six-inch Model 24. Both barrels produced 3-inch groups at 25 yards with a 1000FPS load of 2400 and the .432 250 gr. Keith Bullet. The Forcing cone to cylinder gap with both barrels are .005 relaxed to .007 snug. Serial numbers match on both barrels and the frame. In the attached Factory Letter, Mr. Jinks Provides a through history of the Heavy Duty and Outdoorsman. The last sentence of page 2 begs the question, was this a standard practice? Any input would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Outdoorsman to 1950 Target Factory conversion?

- Thread starter Keith C.

- Start date

Register to hide this ad

I'm not an expert or historian. Roy Jinks has said that S&W would do pretty much what someone would pay them to do. Apparently, the original owner of a .38/44 Outdoorsman wanted a .44 Target and was willing to pay for the conversion. I doubt S&W had a "standard practice" of converting .38/44's to something else. It was fairly common for these guns to be reamed for .357 Magnum, but, typically, outside the factory.

Engine49guy

Member

Very interesting revolver.

Its a shame the factory wont take these type of projects on anymore,

My suspicion is if they hand selected a group of talented individuals and setup a custom shop they would definately generate alot of interest and likely turn a healthy profit.

The thing that catches my attention knowing that the original barrel was the 6" is that the 4" has a more modern sharper shape at the front of the ejector rod shroud where 50's era ones tend to be more rounded off.

My bet would be that when it was sent in the factory could have built him the 4" barrel from a Model 28 barrel or he could have found a 4" 44 barrel somewhere and sent it in for the conversion, and while there why not convert the 6" barrel too since it has that pretty brass bead fs already.

By the mid 70's the Hollywood lore of the .44 Magnum was still a thing but not sure if supply had caught up with demand yet.

On a side note I have a 6" in .44 special thats a few years older than yours, also was factory rebuilt but in 1967 which probably began life as a .45.

While there it was also refinished in bright blue but alas no 4" barrel supplied .

Its a shame the factory wont take these type of projects on anymore,

My suspicion is if they hand selected a group of talented individuals and setup a custom shop they would definately generate alot of interest and likely turn a healthy profit.

The thing that catches my attention knowing that the original barrel was the 6" is that the 4" has a more modern sharper shape at the front of the ejector rod shroud where 50's era ones tend to be more rounded off.

My bet would be that when it was sent in the factory could have built him the 4" barrel from a Model 28 barrel or he could have found a 4" 44 barrel somewhere and sent it in for the conversion, and while there why not convert the 6" barrel too since it has that pretty brass bead fs already.

By the mid 70's the Hollywood lore of the .44 Magnum was still a thing but not sure if supply had caught up with demand yet.

On a side note I have a 6" in .44 special thats a few years older than yours, also was factory rebuilt but in 1967 which probably began life as a .45.

While there it was also refinished in bright blue but alas no 4" barrel supplied .

Interesting the rear sight blade worked equally well on both bbl lengths and using calibers.

Was there a sight in adjustment when changing bbls?

PS Great gun!!

Was there a sight in adjustment when changing bbls?

PS Great gun!!

I sighted in 2" high at 25 yards with the six-inch barrel and after converting to the 4-inch I was one inch lower. I raised it to 2" high and that is where it is today.Interesting the rear sight blade worked equally well on both bbl lengths and using calibers.

Was there a sight in adjustment when changing bbls?

PS Great gun!!

Nesmith

Member

The side plate seam, S&W logo, and dished screw holes look to be indicative of the side plate being over-buffed, something that normally did not occur at the factory (from what I have learned here). Also, is that a plugged lanyard loop hole on the butt? I am definitely not an expert!

If you look at the underlug on the 6 and 1/2" barrel, you will see that the channel in it has been cut for the barrel headed ejector rod. That barrel was made for a transition model and not used. The 4" barrel was made for a transition model too but got run through a mill and had the channel re-cut. Notice how squared off the channel is at the front end.

Excellent observation! I was not aware or knowledgeable enough to notice. Thank You for the input.If you look at the underlug on the 6 and 1/2" barrel, you will see that the channel in it has been cut for the barrel headed ejector rod. That barrel was made for a transition model and not used. The 4" barrel was made for a transition model too but got run through a mill and had the channel re-cut. Notice how squared off the channel is at the front end.

My photography skills are not the greatest. It looks much better in person than in the photos. I am pretty sure you are correct about the plugged lanyard hole.The side plate seam, S&W logo, and dished screw holes look to be indicative of the side plate being over-buffed, something that normally did not occur at the factory (from what I have learned here). Also, is that a plugged lanyard loop hole on the butt? I am definitely not an expert!

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 18

- Views

- 2K

- Locked

Sold/Withdrawn

WTS 44 Magnum 29-2 with factory 5-inch barrel in TN *SOLD*

- Replies

- 0

- Views

- 2K

- Replies

- 0

- Views

- 812

- Replies

- 3

- Views

- 4K