Back in the 90's, NRA bullseye pistol shooters loved Remington blue label std. velocity ammo. Not only was it accurate and precise, but because QC was excellent, and cycled very well in High Standard target pistols with tight chambers.

HV ammo with copper-washed bullets (Winchester was very popular among plinkers) were relegated to hunting and informal shooting (i.e. soda and beer cans

Then, someone started importing "Hansen" brand .22 LR SV ammo from obscure Yugoslavia. To everyone's amazement, this CHEAP ammo shot like a house afire in our target guns, although the powder was filthy and left your hands black after a match. This went on for a few short years, and then they stopped importing it. Year later I found out that it was made by none other than Prvi Partizan.

.22's are funny. In the end, it all depends with what your gun likes; sometimes it shoots the best groups with the cheapest, bulk .22 HV Wally World ammo. BTW, as an aside, in some Latinamerican countries where some shooting is allowed, the .22 LR calber (which is a mouthful in English to say it in Spanish) are called *balita U," or "little U" bullets. This goes back to the letter "U" (for "Union Metallic" which merged with Remington many moons ago) imprinted on the bottom of the casing.

Serious Bench Rest rifle shooters will talk to a supplier and get a brick of different lots of the same brand ammo. And when they find a lot that shoots the best, they'll buy a case of 5,000.

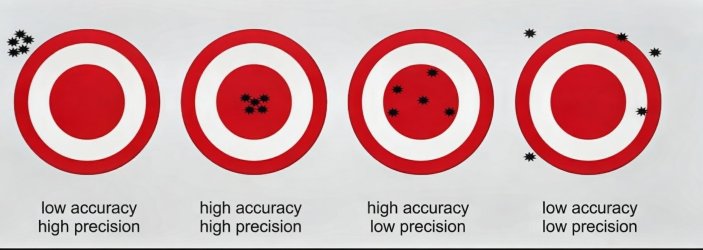

One more thing. Many new shooters use the words accuracy when they mean "precision." There is a difference. HTH.

View attachment 783812View attachment 783813

www.targetsportsusa.com