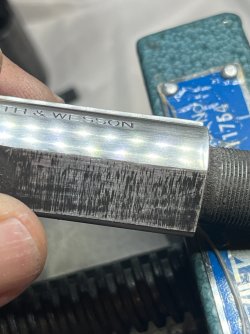

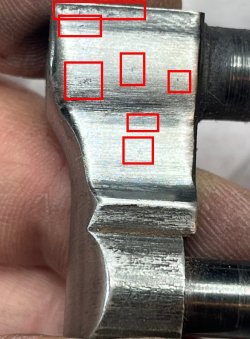

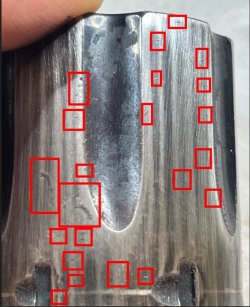

The Tetanus Special went to the range today and performed admirably....especially considering how rusted up the internal mechanism is. My shootin' buddy for the day couldn't believe at first that I was even going to shoot it, but after he saw what it could do he had to try it.......and shot better with the rusty old Smith then he did with his expensive foreign crunchentickers.

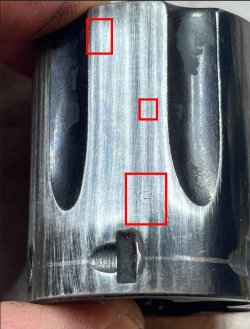

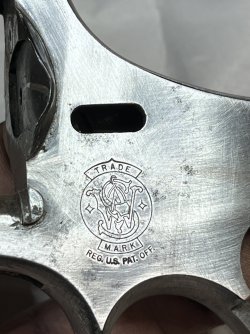

The big surprise of the day is that the Tetanus Special has a sequel: Tetanus Special II came home with us. Number 2 is a round butt 10-8 that looks to have been stored exactly the same was as the original Tetanus Special. You'll be seeing more of Number 2 in the next few weeks.

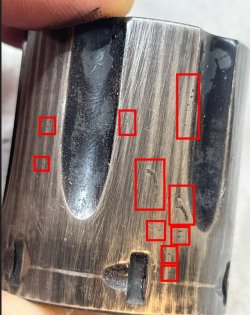

The other big surprise of the day is that an I-frame frankengun also followed me home. That one will get it's own thread, but there's a teaser in the attachments.

The big surprise of the day is that the Tetanus Special has a sequel: Tetanus Special II came home with us. Number 2 is a round butt 10-8 that looks to have been stored exactly the same was as the original Tetanus Special. You'll be seeing more of Number 2 in the next few weeks.

The other big surprise of the day is that an I-frame frankengun also followed me home. That one will get it's own thread, but there's a teaser in the attachments.