"Arrived"

Ok,

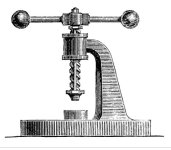

I'm gonna try to be brief but it's hard.... It arrived....It's a pistol (revolver) cartridge loading screw press.

It's marked 32 and 38 on the "BRASS" dies...The plunger is also brass. The rest of the Press is very thick Iron....The cylinder is very thick iron. It took me a while to figure it out but I think they way it works is you load the die from the top of the cylinder...There is a machined stop in the cylinder that matches the taper as I suspected on the die....but its loaded into the cylinder from the top, not the bottom like I thought.

That little button on the cylinder is a "window"...its not for alignment like I thought....As you crank down on the screw press the die is worked down into that window until the die boss is visible. That tells you the 3 rounds are seated to the proper depth when the two holes are perfectly aligned.

So, you then swing open the bottom flange and out drop the loaded rounds...

To load the die you insert the rounds under the bottom...It sounds awkward? but I tried it and it's easy. What I don't like is that there is no protection for the primer.....Just a flat base flange that is solid polished smooth iron....I suppose that would be safe? but I'm not gonna try it.....

It's an early loader so I guess they hadn't worked out the "safety bugs" yet.....It would easily load fast though because you don't have to run the screw press up more than 3 turns after pressing 3 rounds in order to load 3 more....All you do is open the flange and they drop out loaded and ready for 3 more. Also, the handle does "Free spin" like a top, like I thought, to make it easy to operate...It's very neat.

I have to clean it up some. It's a rusty mess.

Unfortunately, its not marked except for the caliber on the dies so my work is cut out for me regarding researching this contraption.

I emailed the seller this morning and he answered me about an hour ago....He said he has no knowledge of this loader but that he bought it about 30 years ago at an estate sale. So, this isn't going to be easy to identify the maker.

I'm now convinced it's pre-1880 though...the 32 and 38 die stamps are not specific to Long or Short so it's an oldee and the fit strongly suggest an early outside lubricated bullet.

Murph