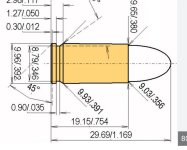

Here's a picture of two 9mm cartridges, reloaded in 2 different batches one day after the other.

The bullets are both Missouri Bullets 125 gr. SWC, both measure .356" dia.

The diameter of the case at the mouth is:

.3775" (red bullet) and .3775" (gold bullet)

The case length (best I can measure an assembled cartridge) is:

0.7430" (red bullet) and 0.7440" (gold bullet)

OK, given that info, both of the cartridges plunk well in my Shield barrel. If I press on the gold bullet cartridge, it bottoms out hard on the rim in the chamber and drops back out when inverted with a little shake. The red bullet cartridge however plunks well, but sticks a little and if I press on it it feels like it's engaging the rifling (a soft lead feeling) and then I have a lot of difficulty getting it out with my finger nails and I have to wiggle the cartridge to get it out of the chamber.

I've had this problem forever and have improved my technique to where I get consistent ammo that plunks reliably, but this problem is only on SOME rounds.

Can anybody enlighten me?

I just had an idea. I'm going to plunk a sample of bullets and measure the depth plunking by the cartridge weight alone, then press the bullets in to see if and how many aren't bottoming out hard metal on metal.

The bullets are both Missouri Bullets 125 gr. SWC, both measure .356" dia.

The diameter of the case at the mouth is:

.3775" (red bullet) and .3775" (gold bullet)

The case length (best I can measure an assembled cartridge) is:

0.7430" (red bullet) and 0.7440" (gold bullet)

OK, given that info, both of the cartridges plunk well in my Shield barrel. If I press on the gold bullet cartridge, it bottoms out hard on the rim in the chamber and drops back out when inverted with a little shake. The red bullet cartridge however plunks well, but sticks a little and if I press on it it feels like it's engaging the rifling (a soft lead feeling) and then I have a lot of difficulty getting it out with my finger nails and I have to wiggle the cartridge to get it out of the chamber.

I've had this problem forever and have improved my technique to where I get consistent ammo that plunks reliably, but this problem is only on SOME rounds.

Can anybody enlighten me?

I just had an idea. I'm going to plunk a sample of bullets and measure the depth plunking by the cartridge weight alone, then press the bullets in to see if and how many aren't bottoming out hard metal on metal.