PSD

Well-known member

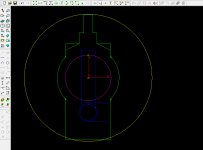

Today I started making a custom barrel for my M69. The project involves removing the 4.25 inch barrel and putting on a custom made 5.25 inch barrel and custom made shroud. The goal is not just to add an inch but also to increase the shroud profile all the way out to the edge of the frame increasing the weight for recoil management, also to put a better quality barrel in because the one in there has issues. I am very busy with my next product release and have very little time so this will be as quick and simple as possible. Really I have NO TIME to mess with this and should not be doing it at all right now but since I took it apart I need to squeeze it in and get it done so I can shoot it again. This will be one solid piece including the sight. Here is what I have done so far:

1- Made leaded steel barrel removal tool, beat it into the barrel until the rifling engraved into the driving bands on the pin. Removed barrel and shroud.

2- Measured frame face and made a CAD drawing using a program called EZCAM.

3- Turned and bored piece of 303 stainless for the shroud blank. Used 303 because it is easy to machine and time is a factor. Doing a simple Dan Wesson system with barrel nut unlike the last barrel project I did with a muzzle brake which was very complicated. (see last barrel project I did on a 500 S&W Magnum HERE.)

4- Rough milled the shroud.

Still needs to be done: Finish shroud profile milling (may have custom cutter ground for this which will set me back a few days to a week). Turn down stainless 8 and 3/8" barrel pulled off a model 629 to make internal barrel. Will post more pix as this comes along.

1- Made leaded steel barrel removal tool, beat it into the barrel until the rifling engraved into the driving bands on the pin. Removed barrel and shroud.

2- Measured frame face and made a CAD drawing using a program called EZCAM.

3- Turned and bored piece of 303 stainless for the shroud blank. Used 303 because it is easy to machine and time is a factor. Doing a simple Dan Wesson system with barrel nut unlike the last barrel project I did with a muzzle brake which was very complicated. (see last barrel project I did on a 500 S&W Magnum HERE.)

4- Rough milled the shroud.

Still needs to be done: Finish shroud profile milling (may have custom cutter ground for this which will set me back a few days to a week). Turn down stainless 8 and 3/8" barrel pulled off a model 629 to make internal barrel. Will post more pix as this comes along.

Attachments

Last edited: