I'm applying extra coats of tung oil, as recommended by the maker, to two pairs of fancy grain Herrett stocks. I've applied five or six coats, allowing at least twenty-four hours drying time and knocking each coat down with OOOO steel wool. My question is this: how best do I apply the last coat? Thin it with mineral spirits? Do I steel-wool it and apply paste wax? Leave it as is? As is will be a little glossier than I'd like so that part is probably answered already. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tung Oil Finish question

- Thread starter JackM

- Start date

Register to hide this ad

Brokenbear

Member

- Joined

- Jan 13, 2017

- Messages

- 30

- Reaction score

- 47

Ideas

consider using extra fine Scotch scruffing pad prior to last coat as hardware store 0000 wool will have oil in it to keep rust down for shelf life

Get a bottle of Birchwood Casey Stock Sheen and follow the directions ..it will allow you to leave the finish at whatever level of shine you want depending how many times you apply and rub ...just rub LIGHTLY ...in direction of the grain

Also get a bottle of Birchwood Casey Stock Wax ...again following the instructions ...remember to rub it enough too create friction heat for the best results and in a circular motion

If at the time you rub it out your last coat and do not like it consider making your final coat with Birchwood Casey TruOil as it has hardeners that the oil you are using simply does not have

For either oil you choose ...time you application where you can do it at 70+ degrees in temp and immediately after applying place in a window sill to direct sunlight ...it will thin the applied material making it flow ridding lines, runs and puddling

Good luck

Bear

consider using extra fine Scotch scruffing pad prior to last coat as hardware store 0000 wool will have oil in it to keep rust down for shelf life

Get a bottle of Birchwood Casey Stock Sheen and follow the directions ..it will allow you to leave the finish at whatever level of shine you want depending how many times you apply and rub ...just rub LIGHTLY ...in direction of the grain

Also get a bottle of Birchwood Casey Stock Wax ...again following the instructions ...remember to rub it enough too create friction heat for the best results and in a circular motion

If at the time you rub it out your last coat and do not like it consider making your final coat with Birchwood Casey TruOil as it has hardeners that the oil you are using simply does not have

For either oil you choose ...time you application where you can do it at 70+ degrees in temp and immediately after applying place in a window sill to direct sunlight ...it will thin the applied material making it flow ridding lines, runs and puddling

Good luck

Bear

I cut every coat of my 100% tung oil 50% with mineral spirits, including the final coat, and rub out every coat with 0000 steel wool. One has to be careful at edges and rub lighter, or the wool will will cut through the finish. After the sheen gets where I want it - 3 to 4 coats or as many as a dozen over several days, I lightly rub the final coat, then use a quality paste wax for a nice soft sheen on the wood.

For steel wool finishing, I prefer 0000 Liberon brand, which comes in a big roll like 2" wide ribbon. I unroll whatever length I need to make a wad suitable for the project at hand and cut it with scissors. It's oil free too. My 1 kilogram roll has lasted for years. It does shed, but being oil free, it doesn't stick and blows away or vacuums up easily.

For steel wool finishing, I prefer 0000 Liberon brand, which comes in a big roll like 2" wide ribbon. I unroll whatever length I need to make a wad suitable for the project at hand and cut it with scissors. It's oil free too. My 1 kilogram roll has lasted for years. It does shed, but being oil free, it doesn't stick and blows away or vacuums up easily.

Last edited:

kleiss1

Member

I use 5 or more coats Birchwood Casey Tru-Oil and after a week or more of drying use there Stock Sheen.

- Joined

- Apr 4, 2006

- Messages

- 19,794

- Reaction score

- 31,631

How you do the last coat depends on how glossy you like the finish to be. If you like a satin finish then yes gently go over it with the 0000 steel wool. Personally I leave the last coat as is and do nothing except let it dry.

You really can't put too many coats on, but 5 or 6 is about right for grips. If a year from now you want to touch them up, just hit them lightly again with the steel wool and apply another coat or two. I like the somewhat glossier look of leaving the last coat as is. I have never diluted the Tung Oil - I just use it right out of the can.

I refinished a Marlin Rifle stock with 100% pure Tung oil and applied about a dozen coats initially and then another coat or two a few years later. The rifle still looks spectacular! I love the Tung Oil finish and have used it for 40 years on gun wood, furniture, moulding and frames. I still have the original can of Hopes 100% Tung Oil that I purchased back then - a little really goes a long way!! The best part is since Tung Oil that is 100% pure has no additives it lasts forever with no shelf life.

NOTE: Some confuse 100% Tung Oil with products that contain Tung oil but are blended with other chemicals. Those do not have an infinite shelf life.

You really can't put too many coats on, but 5 or 6 is about right for grips. If a year from now you want to touch them up, just hit them lightly again with the steel wool and apply another coat or two. I like the somewhat glossier look of leaving the last coat as is. I have never diluted the Tung Oil - I just use it right out of the can.

I refinished a Marlin Rifle stock with 100% pure Tung oil and applied about a dozen coats initially and then another coat or two a few years later. The rifle still looks spectacular! I love the Tung Oil finish and have used it for 40 years on gun wood, furniture, moulding and frames. I still have the original can of Hopes 100% Tung Oil that I purchased back then - a little really goes a long way!! The best part is since Tung Oil that is 100% pure has no additives it lasts forever with no shelf life.

NOTE: Some confuse 100% Tung Oil with products that contain Tung oil but are blended with other chemicals. Those do not have an infinite shelf life.

Wee Hooker

Member

I used to use a product called rottenstone to buff fine wood finish's after the final coat cured. I could regulate gloss by cutting with water or oil to get different results. Good stuff and a little goes a long way.

MichiganScott

Member

I cut my oil 50:50 with mineral spirits. I usually buff off the first couple of coats down to the wood to make sure that the pores in the wood are completely filled. After that, I don't buff between coats unless the finish has picked up dust or other contaminates. I find anywhere from 5-7 coats is usually just about right.

I have recently found that Mr. Clean Erasers will take off the shine and give a nice matte finish. If I want a dull finish like on military rifles, I will rub it out with automotive rubbing compound. Paste wax like Johnson's or Renaissance wax will protect the wood and leave a matte finish.

I have recently found that Mr. Clean Erasers will take off the shine and give a nice matte finish. If I want a dull finish like on military rifles, I will rub it out with automotive rubbing compound. Paste wax like Johnson's or Renaissance wax will protect the wood and leave a matte finish.

DWalt

Member

Many products advertised as containing Tung oil contain none. I always thin both tung oil and products like Tru-Oil with mineral spirits. white Scotchbrite pads work well to cut shine, followed by Johnson's Paste Wax.

Many products advertised as containing Tung oil contain none.

I've read that statement many many times on the all knowing Net. The best I can trace it back to is an article in Fine Woodworking some years ago,,I forget the authors name. He was specificly refering to Homer Formby products and their Tung Oil Finish,,stating that the stuff contained no tung oil at all.

He never put forth any proof or spec info, just his statement, But that statement has really stuck.

True, the stuff is not 100% tung oil, it's at least 60% mineral spirits. It places it in a catagory commonly known as 'wiping varnishes' which is what it's sold as.

Wether that's an o'fficial professional wood finishers term or not I don't know but it's a good descriptive one. Several products from different mfg'rs are the same mix & make up.

Wether the base oil is linseed, tung, or another veg based oil,,use one that gets the results you like.

Long, short or medium oil varnishes can be had in any oil varnish. That term only describes the % of oil vs the vehicle. The higher the oil content to the vehicle (min spirits generally, though turp can be used and there are lots of synthetic mixes), the longer it takes to dry.

The advantage in most cases to a 'long oil varnish' is a more flexible finish that won't crack and craze, but type of oil base used and the drying conditions, wood moisture content ect all figure in. They are slower drying as the oil content increases.

Way too much for the average hobby person wanting to finish a set of grips most times. So the simple from the bottle Linspeed, Tru-Oil, or wiping varnish type finishes (wether they are Linseed, Tung or other oil based) are about the easiest to use.

I like the Tung oil varnish, drys fast(er) and hard than linseed oil based varnishes for me at least. I sand in the first couple coats to fill the grain but first heavily stain the wood w/ alcohol stain.

..

The sanding fills the grain and will lighten the staining some resulting in the silk smooth surface I'm after. Then you can build up a finish on top as deep as you want or leave it looking like a hand rubbed in oil finish without any build up by applying the thinnest of coating.

A final rubdown w/rottenstone cuts the glare,, and there you are.

Set it in the corner and let it cure for a week or 2 after the final rubdown. Go do something else and just let it set.

OK guys, get ready for the ladies to start clutching their pearls; I use Minwax Tung Oil Finish and get great results

. A lot less horsing around than with "gen-U-whine" tung oil. Two coats gets the job done right. Easy to touch up again later too, just like a "real" tung oil finish.

. A lot less horsing around than with "gen-U-whine" tung oil. Two coats gets the job done right. Easy to touch up again later too, just like a "real" tung oil finish.

I have had completely satisfactory results with "Tru-oil" too.

The secret is to not apply too many coats, which avoids the phony plastic look of so many DIY wood finishing projects.

I have had completely satisfactory results with "Tru-oil" too.

The secret is to not apply too many coats, which avoids the phony plastic look of so many DIY wood finishing projects.

Attachments

- Joined

- Apr 4, 2006

- Messages

- 19,794

- Reaction score

- 31,631

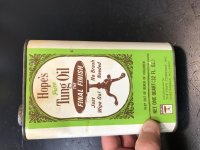

This can of pure Tung Oil is almost 40 years old and is just under half full. I can not believe how far it goes.

The can in the photo is 100% PURE Tung Oil (nothing to separate, evaporate or go bad). MANY finishes today are Tung Oil BLENDS that only contain some Tung Oil and can be deceiving. So be careful of what you purchase!

I apologize in advance if I am wrong, but I believe that the can of Minwax Tung Oil Finish in Warren Sear's post is NOT PURE Tung Oil - actually yes, he stated that. Not saying it's bad stuff - just pointing that out so someone wanting PURE T/O gets what they want. ALSO------ T/O since it is a natural product is not harmful when hand rubbing it in. The warmth from ones hand helps it get into the woods pores. Most TO Blends have mineral spirits and other stuff that I would not want to hand rub.

PS: 100% T/O can also be applied over Stains so if you want a specific color T/O is a pleasure to work with.

The can in the photo is 100% PURE Tung Oil (nothing to separate, evaporate or go bad). MANY finishes today are Tung Oil BLENDS that only contain some Tung Oil and can be deceiving. So be careful of what you purchase!

I apologize in advance if I am wrong, but I believe that the can of Minwax Tung Oil Finish in Warren Sear's post is NOT PURE Tung Oil - actually yes, he stated that. Not saying it's bad stuff - just pointing that out so someone wanting PURE T/O gets what they want. ALSO------ T/O since it is a natural product is not harmful when hand rubbing it in. The warmth from ones hand helps it get into the woods pores. Most TO Blends have mineral spirits and other stuff that I would not want to hand rub.

PS: 100% T/O can also be applied over Stains so if you want a specific color T/O is a pleasure to work with.

Attachments

Last edited:

This is a stock done in a "tung oil" forty years ago.Im sure it's one of the wiping varnishes rather than 100% pure,I don't remember the brand anymore.Knocked the gloss off at the end and every now and again it gets a coat of wax

I used Formby's to finish my new Springfield Armory M1-A stock five years ago and I am still enjoying the results.

However, I decided to use MinWax Poly "Clear Satin" as the final finish.

I also spoke with Formby's Customer Support several times. They were always very helpful. The representatives stated that I should wait 21-30 days after the final coat of tung oil finish to allow adequate time for drying and curing before I applied any final product (MinWax Poly in my case).

From Formby's:

Wipe-On-Poly is a great "bridge" product between tung oil and regular polyurethane. Wipe-On-Poly has the durability of polyurethane and the ease of application of a tung oil finish.

1.) Allow the Formby's Tung Oil Finish to cure for 20-30 days

1.) Lightly scuff sand the Tung Oil Finish with 220-grit sandpaper

2.) Remove sanding dust using a soft, lint-free cloth dampened in 100% pure mineral spirits

3.) Allow to dry (mineral spirits will evaporate/flash off)

4.) Apply 1-3 thin coats of the Minwax Wipe-On-Poly following label instructions.

However, I decided to use MinWax Poly "Clear Satin" as the final finish.

I also spoke with Formby's Customer Support several times. They were always very helpful. The representatives stated that I should wait 21-30 days after the final coat of tung oil finish to allow adequate time for drying and curing before I applied any final product (MinWax Poly in my case).

From Formby's:

Wipe-On-Poly is a great "bridge" product between tung oil and regular polyurethane. Wipe-On-Poly has the durability of polyurethane and the ease of application of a tung oil finish.

1.) Allow the Formby's Tung Oil Finish to cure for 20-30 days

1.) Lightly scuff sand the Tung Oil Finish with 220-grit sandpaper

2.) Remove sanding dust using a soft, lint-free cloth dampened in 100% pure mineral spirits

3.) Allow to dry (mineral spirits will evaporate/flash off)

4.) Apply 1-3 thin coats of the Minwax Wipe-On-Poly following label instructions.

- Joined

- Apr 4, 2006

- Messages

- 19,794

- Reaction score

- 31,631

This is a stock done in a "tung oil" forty years ago.Im sure it's one of the wiping varnishes rather than 100% pure,I don't remember the brand anymore.Knocked the gloss off at the end and every now and again it gets a coat of wax

Still looks good from here!

Might take a look over here...jus' sayin' :

Wood Cleaning Article - Civilian Marksmanship ProgramCivilian Marksmanship Program

Wood Cleaning Article - Civilian Marksmanship ProgramCivilian Marksmanship Program

I do what Wee Hooker does. After the last coat drys (5-7 days) make a paste of rottenstone and mineral oil. Using a very soft cloth (old t-shirts), rub out to the desired sheen. This knocks the "glossy" look down and adds depth to the smooth sheen.

here's a recent thread for reference

http://smith-wessonforum.com/s-w-re...14-tung-oil-finish.html?513014=#post139502682

http://smith-wessonforum.com/s-w-re...14-tung-oil-finish.html?513014=#post139502682

I'm applying extra coats of tung oil, as recommended by the maker, to two pairs of fancy grain Herrett stocks. I've applied five or six coats, allowing at least twenty-four hours drying time and knocking each coat down with OOOO steel wool. My question is this: how best do I apply the last coat? Thin it with mineral spirits? Do I steel-wool it and apply paste wax? Leave it as is? As is will be a little glossier than I'd like so that part is probably answered already. Thanks in advance.

I am a fan of Tung Oil finishes. Hand rubbing 100% tung oil presents best results for my needs. I generally cut the oil with mineral spirits or turpentine for the first application, allowing the solvent to carry the oil deeper into the wood. Subsequent applications are not thinned, and are very light to allow for absorption, but not sticky caking messes. More is not better for an application, rather have more single applications. If the manufacturer suggests tung oil, use tung oil. "Tung oil finishes" may or may not contain tung oil. Check the ingredients or MDS sheet. Last I checked, years ago, Minwax had no tung oil in it. Not a fan of tung oil "finishes" if I want a true long lasting oil finish. I have learned to enjoy a final coat or two of Tru-Oil for certain applications, but not all. For abrasives, I steer clear of steel wool. I have had issues in the past when over time micro bits of steel wool under the finish will oxidize and make a mysterious mess. I use Scotch-Brite type pads that are available in many varieties at woodworking supply places. Best of luck.

Similar threads

- Replies

- 6

- Views

- 706

- Replies

- 4

- Views

- 646

- Locked

- Replies

- 3

- Views

- 758