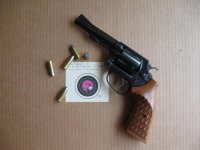

I've enjoyed shooting .38 S&W with 200g bullets and had satisfactory results from 32-1, 33-1, PPS, and Enfield. (I've also been very happy with 158g bullet loads, too.) Depending on the different profiles of the 200g bullets I've used & the seating depths I've tried, I've generally used 2.5g, 2.6g or 2.7g of Win 231 & these loads run 600-650 or so from a 4" barrel with consistent velocities and easy extraction.

I've got some Bullseye but haven't done much with it yet; from what I can tell looking at various load tables, anything that works with 2.5g of Win231 is often about 2g or so with BE. I certainly defer to Ken Waters &

Pet Loads.

If your .38 S&W Victory is solid, you should have no problem pushing a 200g bullet up to 700fps average, according to Ed Harris, although British Mk. I and American-made .38 S&W Super Police factory loads were kept to low 600's to meet British military requirements & avoid blowing up too many weak top-breaks here on this side of the pond

Bored-out Victory models have had lots of problems over the years with .38 SPL cases splitting, or bulging & jamming the cylinder, as the original .38 S&W chambering was slightly larger in diameter than the 38SPL. So, by boring out the cylinders for .38 SPL, they simply allowed the longer .38 SPL case to fit into the chambers lengthwise. By sticking with .38 S&W brass, you should be fine. The slightly longer "jump" to the cylinder throat won't make too much practical difference to your accuracy, I believe.

I don't think I've ever slugged the barrel on my Victory, but I've checked a couple of 32-1 and 33-1 and they were .359 groove diameter. I suspect, but don't know, that the Victory is the same, but it might be a bit fatter. British MILSURP guns and perhaps some other gunmakers' brands ran larger, up to the low-to-mid-.360's. If your revolver has a big groove diameter, I would expect problems with stabilizing any bullet of .358-ish diameter, but especially a 200g bullet, because the rifling can't "grab" enough of the bullet to impart rotation. If groove/bullet diameter is a decent match, your gun will do just fine with 200g bullets.

If you can cast your own bullets, you can "beagle" the mold to increase the diameter a few thousandths to work better in your gun, if necessary. Should you need help on beagling and slugging, just let us know.

BTW, 148-150g wadcutters are a great choice for the .38 S&W, as bullet weights are so similar to the 145-46g LRN factory ammo. Make it easy on yourself and load the wadcutter "long," i.e. crimp it in a lube groove, and your resulting COL will be closer to a .38 SPL round. . .That means more case capacity, less pressure, and thus a greater margin of safety with a gun & cartridge with which you are balancing a variety of specifications. When you're already juggling fast powders, possibly heavy bullets, chamber dimensions, bore dimensions, and bullet dimensions, there's no need to complicate things still more by loading a wadcutter flush with the case mouth. I'm sure it can be done, but I don't do it FWIW

Happy shooting, and let us know how you're coming along.