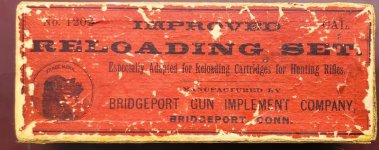

Just purchased this kit. I thought it was a 44 Winchester reloader but it's a rare 44 Russian "IMPROVED" reloading kit. I've never seen one so I thought I'd share.

Very interesting in that the loading die, plunger, and base are SOLID BRASS, Nickel plated.

It also has a tool I've never seen. A hand held bullet lubricator. It operates like a syringe. Very neat.

It has a 23 grain FF POWDER SCOOP, PRIMER PUNCH, mouth sizer, and rare iron handle primer tool.

It also came with a 44 Russian bullet mold that I have soaking right now to loosen the rust for cleaning.

I will post a photo later. The mold is an early outside lubricated bullet! Which is also quite rare.

These kits are not well documented. I keep running into examples I've never seen before.

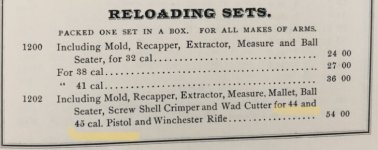

Also the photo of the catalog listing is for the older kit. I do not have any information on an IMPROVED KIT. It does prove however that the 1202 kit covered the 44 cal pistol.

Murph

Very interesting in that the loading die, plunger, and base are SOLID BRASS, Nickel plated.

It also has a tool I've never seen. A hand held bullet lubricator. It operates like a syringe. Very neat.

It has a 23 grain FF POWDER SCOOP, PRIMER PUNCH, mouth sizer, and rare iron handle primer tool.

It also came with a 44 Russian bullet mold that I have soaking right now to loosen the rust for cleaning.

I will post a photo later. The mold is an early outside lubricated bullet! Which is also quite rare.

These kits are not well documented. I keep running into examples I've never seen before.

Also the photo of the catalog listing is for the older kit. I do not have any information on an IMPROVED KIT. It does prove however that the 1202 kit covered the 44 cal pistol.

Murph

Attachments

Last edited: