Well I finally found one. Many years searching!!

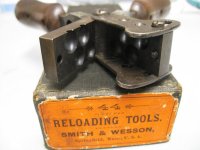

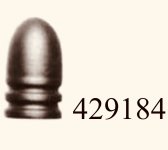

The “Improved Model” post 1886 44 Russian Peanut Bullet Mold. Manufactured by Smith & Wesson beginning in 1887- Approximately 1912.

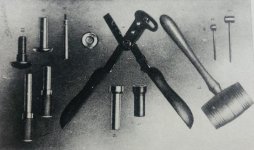

Usually as part of a reloading boxed kit with reloading tools and Mallet.

These are pretty hard to find. This one has matching assembly numbers and is in wonderful overall condition.

Anyone else have one in their collection? Maybe they can post a photo of?

Murph

The “Improved Model” post 1886 44 Russian Peanut Bullet Mold. Manufactured by Smith & Wesson beginning in 1887- Approximately 1912.

Usually as part of a reloading boxed kit with reloading tools and Mallet.

These are pretty hard to find. This one has matching assembly numbers and is in wonderful overall condition.

Anyone else have one in their collection? Maybe they can post a photo of?

Murph

Attachments

-

4204C0B9-F887-4375-AFEC-15E425F56BE6.jpg41 KB · Views: 160

4204C0B9-F887-4375-AFEC-15E425F56BE6.jpg41 KB · Views: 160 -

A7760290-B3C5-4211-810C-B9BACB0C2747.jpg31 KB · Views: 147

A7760290-B3C5-4211-810C-B9BACB0C2747.jpg31 KB · Views: 147 -

39794287-2F1D-434E-A003-7B38110BA6B9.jpg31.4 KB · Views: 128

39794287-2F1D-434E-A003-7B38110BA6B9.jpg31.4 KB · Views: 128 -

D36BA9D8-BC2F-489E-96DA-78A780D7C096.jpg29.2 KB · Views: 134

D36BA9D8-BC2F-489E-96DA-78A780D7C096.jpg29.2 KB · Views: 134 -

C2E0A5E1-DE38-4925-92C3-DA2118FBDFB4.jpg35 KB · Views: 143

C2E0A5E1-DE38-4925-92C3-DA2118FBDFB4.jpg35 KB · Views: 143

Last edited: