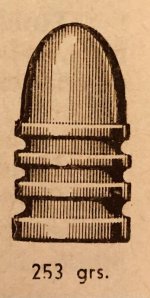

Rare mold

That 32 you have is a rare one. That’s a 32-44 Target Peanut mold.

Murph

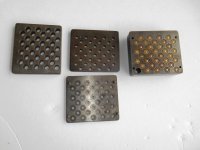

I regularly use the mold of 44 and 38

That 32 you have is a rare one. That’s a 32-44 Target Peanut mold.

Murph