I am sorting a bucket of range brass, separating the .223 and 5.56 brass. I'm aware of the case wall thickness differences between the two, but does that thickness come into play when you are reloading ? Do you separate the brass ? Do you treat the two as one ? My loads and never "hot", and I load for plinking and Coyotes. Just need something to worry about.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5.56 vs .223 range brass

- Thread starter Cope!

- Start date

Register to hide this ad

I load both with the same loads which are not max. loads. I do watch for crimped primers that the military rounds use. When those get deprimed, I use a case trimmer tool (for reaming the inside of case neck) to put a slight bevel on the primer pocket.

Ivan the Butcher

Member

I think that having them mixed won't hurt anything except group size from a bolt action. You could still separate them and load them the same and fire them separately.

Not all military 5.56 have the same dimensions internally. I have vergin LC brass that was for ball ammo and vergin LC brass that was for SAW belt fed ammo. They have different web thickness (Because the SAW has loose chamber dimensions for heat reasons) The SAW brass has micro less capacity and much greater strength. I use it for bolt action 1000 yard loads. With high BC bullets it gets 3 to 5 inch groups depending which stock it is in. (That ammo is over AR pressure requirements and too long for AR Mags and chambers) but uses the same powder charge as my 62 grain load (which I put in any brass.)

Ivan

Not all military 5.56 have the same dimensions internally. I have vergin LC brass that was for ball ammo and vergin LC brass that was for SAW belt fed ammo. They have different web thickness (Because the SAW has loose chamber dimensions for heat reasons) The SAW brass has micro less capacity and much greater strength. I use it for bolt action 1000 yard loads. With high BC bullets it gets 3 to 5 inch groups depending which stock it is in. (That ammo is over AR pressure requirements and too long for AR Mags and chambers) but uses the same powder charge as my 62 grain load (which I put in any brass.)

Ivan

nbedford

Member

Reminder with 556 mil. brass; always measure the overall case length after resizing. I've found some that were unbelievable.

I've loaded 223 for 55yrs. The only difference I saw was GI 5.56 had less case volume than commercial 223. I never did bother to check the case volume of commercial Mil Spec 5.56. I loaded for single shot Ruger and bolt actions. My load was 55gr Hornady bullet over BCL-2. Very satisfactory 400yd varmit load.

- Joined

- Aug 9, 2005

- Messages

- 9,207

- Reaction score

- 11,421

Some range brass may have been fired many times and that's why it became range brass. It's hard to tell just by looking at it, though true once-fired brass looks like once-fired brass. It appears new and often retains distinct factory anneal discoloration in the shoulder/ neck area.

I've picked up range brass but no longer do. Brass may be difficult to find, but that won't always be. Once-fired with the same headstamp will be available again and it's better brass than something with an unknown history. The price may go up, but it will likely still be a bargain when one considers how many times it can be safely loaded.

I know many are opposed to buying or using a case gauge, but if you want 100% reliability in a semi-auto, a properly used case gauge is the only way to go. They're inexpensive, simple, and take but a second to use.

I've picked up range brass but no longer do. Brass may be difficult to find, but that won't always be. Once-fired with the same headstamp will be available again and it's better brass than something with an unknown history. The price may go up, but it will likely still be a bargain when one considers how many times it can be safely loaded.

I know many are opposed to buying or using a case gauge, but if you want 100% reliability in a semi-auto, a properly used case gauge is the only way to go. They're inexpensive, simple, and take but a second to use.

- Joined

- Oct 17, 2006

- Messages

- 7,772

- Reaction score

- 7,184

OK, about military vs commercial brass. You generally see a definite difference in .30 brass. In certain product lines/brands it may get chancy in part because of specialized military contracts.

The comment above about brass intended for use in a SAW/M249 being different is interesting. First time I've heard that. From a supply chain standpoint, I've gotta question that. Is there different nomenclature/classification for that round? OK, it's probably shipping already in disintegrating link belts, but that's not generally sufficient for the OCD supply folks.

However, 5.56 mm/.223 was developed originally as a military round. I haven't found a significant difference between commercial and military brass. I just weighed Federal and Winchester military spec brass and Remington commercial. The Federal & Remington (developed the round) weighed the same 92.5 gr each, the Winchester was 89.5 gr. As someone noted above, any slight differences aren't an issue unless you're going for bleeding edge velocities.

Range brass that still has the primer crimp should be once fired.

The comment above about brass intended for use in a SAW/M249 being different is interesting. First time I've heard that. From a supply chain standpoint, I've gotta question that. Is there different nomenclature/classification for that round? OK, it's probably shipping already in disintegrating link belts, but that's not generally sufficient for the OCD supply folks.

However, 5.56 mm/.223 was developed originally as a military round. I haven't found a significant difference between commercial and military brass. I just weighed Federal and Winchester military spec brass and Remington commercial. The Federal & Remington (developed the round) weighed the same 92.5 gr each, the Winchester was 89.5 gr. As someone noted above, any slight differences aren't an issue unless you're going for bleeding edge velocities.

Range brass that still has the primer crimp should be once fired.

I'm aware of the case wall thickness differences between the two, but does that thickness come into play when you are reloading ?

The thicker cases holds slightly less powder. A compressed load in a 223 case will overflow the 5.56 case. I've loaded loads in 223 cases that wouldn't work in 5.56 brass. Pressure can vary as well.

If 5.56 range brass has had the primer pocket decrimped, the only thing you know for sure is it is used. I reloaded .223/5.56 for a single shot rifle and for my "accurate loads" I worked them up by headstamp. I never weighed cases (this was 30+ years ago) so I could not determine case capacity, but when I found "The Load" I continued with loading the same head stamp.

I no longer reload 223/5.56 and don't pick up any at the range (a lot of 5.56 and 9mm is left behind, but I mostly leave it for someone else).

I no longer reload 223/5.56 and don't pick up any at the range (a lot of 5.56 and 9mm is left behind, but I mostly leave it for someone else).

Last edited:

- Joined

- Aug 9, 2005

- Messages

- 9,207

- Reaction score

- 11,421

There is less difference in case capacity with both commercial and military brass than than I originally thought, but it's there. Even with an accurate rifle, I doubt you'll see much difference in accuracy between mixed brass and all one headstamp brass if you're only shooting at 100 or 200 yards. I suspect differences would become greater, however, as distances increase. That's just a guess; I haven't confirmed it but I'm sure others have.

Still, it's unlikely that loads using mixed brass with an unknown history will be more accurate than well developed loads using brass with the same headstamp that have been fired the same number of times, unless you're doing the testing with a rifle or carbine that's not very accurate anyway.

Still, it's unlikely that loads using mixed brass with an unknown history will be more accurate than well developed loads using brass with the same headstamp that have been fired the same number of times, unless you're doing the testing with a rifle or carbine that's not very accurate anyway.

There are a lot of myths about military brass, and things have also changed a bit over the years.

Let's talk about 7.62 NATO and .308 Win first as the situation was fairly straight forward until fairly recently (around 2009).

In the past you could rely on 7.62 NATO brass being thicker walled and significantly lower volume than .308 Win brass. That was done intentionally to give the case a thicker web to prevent head separations in machine guns like the M60, where the head space was usually very generous.

Generally speaking, after the M14 dropped out of common use, handloaders avoided non match 7.62 NATO brass as most of it was loaded as M80 ball or M62 tracer rounds, and fired in an M60, with the result that the cases were almost always stretched excessively.

Match brass ammo however was highly sought after as the quality was usually good and the cases were not abused. They also didn't have a crimped in primer and were easy to process. They still however had the thicker web and smaller internal volume as it was the same brass, just more carefully selected by lot, then head stamped as match brass and assembled without a primer crimp.

The difference in powder charge to achieve the same velocity was normally in the 1.0 to 1.5 grain range - fairly significant if you were loading a fairly warm load for .308 and dropped it in a 7.62 NATO case by mistake. Since I had 5 gallon bucket fulls of LC Match brass, I loaded everything into it and never bothered to develop loads for .308 commercial cases and if by chance a .308 case found its way into a batch the result was lower than normal pressure.

However that has now changed.

When Federal started producing the latest iteration of M118LR as well as Mk 316 Mod 0 for the Navy, they started using their Federal Gold Medal Match brass, which was head stamped as Lake City Match brass, as Lake City is operated by Federal. That change meant this newer LC Match brass has the same volume as commercial .308 brass and in particular commercial FGGM brass, which is what it is. I found this out when I started to run low on military match brass, and had access to significant amounts of once fired FGGM .308 brass from accuracy testing by HS Precision on our club range.

I started developing loads in FGGM brass and then bought some newer production Lake City Match brass and discovered I was using the same load in each. A little research uncovered the switch to FGGM brass when Federal got the M118LR contract.

To make things even more confusing, you can also find Federal packaged Lake City brass sold as a reloading components stamped as regular non match military head stampeded Lake City brass. It's the same brass they use in their civilian XM-80 load, and again it has the same internal volume as commercial .308 brass. So can't rely on military marked non match brass all being thick walled either.

In short, the former truth that 7.62 NATO brass was thicker and lower volume than commercial .308 brass is no longer always the case.

----

5.56 NATO and .223 Rem

This is much more straight forward. The case was designed from the start for the AR-15, as an upsized .222 Rem, and Stoner stated once that had be known Remington was developing the .222 Remington Magnum, he would not have bothered with the .223.

Any bottle necked case stretches at the point just behind the spot where the case still adheres to the chamber. Under pressure the case expands to seal against the chamber and it does so all the way back to the point where the case wall is too thick to expand. That depends on the pressure of the case, the thickness of the case wall, and the diameter of the case as the smaller the diameter the more resistant it is to pressure.

If you've ever had incipient head separations with 7.62 NATO and 5.56 NATO brass you've probably noted the separation line develops fairly low in the 7.62 NATO case maybe 1/4" to 3/8" above the extractor cut. In contrast, it's about 40% of the way up the side of the case in the 5.56 NATO.

That's why you see a great deal of difference between 7.62 NATO and .308 brass. There's a lot of case in front of that separation line in the 7.62 NATO and .308 Win, and that makes it much more likely for a case to separate and leave part of the case in the chamber. That's why 7.62 NATO brass ended up with thicker case walls than .308 Win.

However, you'll find no significant difference in the case wall thickness and internal volume of most military 5.56 NATO brass and civilian .223 Rem brass. There's no need to construct it differently to avoid a separation that leaves the front portion of the case in the chamber.

Someone above suggested that 5.56 NATO ammo made to be used in belt fed weapons is different and has thicker case walls. I'll be really charitable and say that I'm dubious. That is no different than putting an entirely new round in the logistics system, and not just in the warehouse and transportation system but all the way back to the manufacture of components, meaning to separate types of 5.56 NATO cases would have to be made and kept separate through the manufacturing process.

That's just not going to happen. If it was felt case walls needed to be thicker for the SAW, they'd just use a thicker case on all 5.56 NATO ammo.

In short, all domestically produced .223 Rem or 5.56mm NATO ammo has very similar case capacity and for all practical purposes the cases are interchangeable.

The potential exception are 5.56/.223 cases manufactured in some eastern european countries. Some of them are *reported* to be lower capacity, but I've never personally come across a valid example.

Let's talk about 7.62 NATO and .308 Win first as the situation was fairly straight forward until fairly recently (around 2009).

In the past you could rely on 7.62 NATO brass being thicker walled and significantly lower volume than .308 Win brass. That was done intentionally to give the case a thicker web to prevent head separations in machine guns like the M60, where the head space was usually very generous.

Generally speaking, after the M14 dropped out of common use, handloaders avoided non match 7.62 NATO brass as most of it was loaded as M80 ball or M62 tracer rounds, and fired in an M60, with the result that the cases were almost always stretched excessively.

Match brass ammo however was highly sought after as the quality was usually good and the cases were not abused. They also didn't have a crimped in primer and were easy to process. They still however had the thicker web and smaller internal volume as it was the same brass, just more carefully selected by lot, then head stamped as match brass and assembled without a primer crimp.

The difference in powder charge to achieve the same velocity was normally in the 1.0 to 1.5 grain range - fairly significant if you were loading a fairly warm load for .308 and dropped it in a 7.62 NATO case by mistake. Since I had 5 gallon bucket fulls of LC Match brass, I loaded everything into it and never bothered to develop loads for .308 commercial cases and if by chance a .308 case found its way into a batch the result was lower than normal pressure.

However that has now changed.

When Federal started producing the latest iteration of M118LR as well as Mk 316 Mod 0 for the Navy, they started using their Federal Gold Medal Match brass, which was head stamped as Lake City Match brass, as Lake City is operated by Federal. That change meant this newer LC Match brass has the same volume as commercial .308 brass and in particular commercial FGGM brass, which is what it is. I found this out when I started to run low on military match brass, and had access to significant amounts of once fired FGGM .308 brass from accuracy testing by HS Precision on our club range.

I started developing loads in FGGM brass and then bought some newer production Lake City Match brass and discovered I was using the same load in each. A little research uncovered the switch to FGGM brass when Federal got the M118LR contract.

To make things even more confusing, you can also find Federal packaged Lake City brass sold as a reloading components stamped as regular non match military head stampeded Lake City brass. It's the same brass they use in their civilian XM-80 load, and again it has the same internal volume as commercial .308 brass. So can't rely on military marked non match brass all being thick walled either.

In short, the former truth that 7.62 NATO brass was thicker and lower volume than commercial .308 brass is no longer always the case.

----

5.56 NATO and .223 Rem

This is much more straight forward. The case was designed from the start for the AR-15, as an upsized .222 Rem, and Stoner stated once that had be known Remington was developing the .222 Remington Magnum, he would not have bothered with the .223.

Any bottle necked case stretches at the point just behind the spot where the case still adheres to the chamber. Under pressure the case expands to seal against the chamber and it does so all the way back to the point where the case wall is too thick to expand. That depends on the pressure of the case, the thickness of the case wall, and the diameter of the case as the smaller the diameter the more resistant it is to pressure.

If you've ever had incipient head separations with 7.62 NATO and 5.56 NATO brass you've probably noted the separation line develops fairly low in the 7.62 NATO case maybe 1/4" to 3/8" above the extractor cut. In contrast, it's about 40% of the way up the side of the case in the 5.56 NATO.

That's why you see a great deal of difference between 7.62 NATO and .308 brass. There's a lot of case in front of that separation line in the 7.62 NATO and .308 Win, and that makes it much more likely for a case to separate and leave part of the case in the chamber. That's why 7.62 NATO brass ended up with thicker case walls than .308 Win.

However, you'll find no significant difference in the case wall thickness and internal volume of most military 5.56 NATO brass and civilian .223 Rem brass. There's no need to construct it differently to avoid a separation that leaves the front portion of the case in the chamber.

Someone above suggested that 5.56 NATO ammo made to be used in belt fed weapons is different and has thicker case walls. I'll be really charitable and say that I'm dubious. That is no different than putting an entirely new round in the logistics system, and not just in the warehouse and transportation system but all the way back to the manufacture of components, meaning to separate types of 5.56 NATO cases would have to be made and kept separate through the manufacturing process.

That's just not going to happen. If it was felt case walls needed to be thicker for the SAW, they'd just use a thicker case on all 5.56 NATO ammo.

In short, all domestically produced .223 Rem or 5.56mm NATO ammo has very similar case capacity and for all practical purposes the cases are interchangeable.

The potential exception are 5.56/.223 cases manufactured in some eastern european countries. Some of them are *reported* to be lower capacity, but I've never personally come across a valid example.

I've never separated .223 and 5.56 brass unless I happened to have a large batch and want some matching headstamps for a particular load. I've converted both cases to a 6mm Mongoose wildcat round and cannot detect any difference in powder levels between the two. Commercial cases, commercial govt-contract cases, and Mil cases all load to the same level with the charge of powder I use.

Case capacity can vary between manufacturers of 223, as well as 223 vs 5.56, but I have seen the difference in some cases. I used to shoot a compressed load in my 223 that would overflow any 5.56 cases that got mixed into my 223's. The first time this happened, I thought my powder measure had gone wacky till I figured out that I gotten a 5.56 mixed in with my 223 cases. I've read claims of less than 1 grain difference to almost 3 grains between the two cases.

Spajohn

Member

- Joined

- Oct 17, 2006

- Messages

- 7,772

- Reaction score

- 7,184

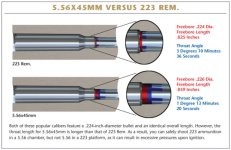

It's not a headspace difference in cartridges. If you'd read your own attachment, you'd have noticed that the significant difference is in the chamber leade. That is, the freebore length and the angle of the throat taper at the start of the rifling.

The higher pressure 5.56 MM round can get a significant pressure boost in the tighter .223 chamber.

The higher pressure 5.56 MM round can get a significant pressure boost in the tighter .223 chamber.

Last edited:

This 223 vs 5.56 has been made into a problem by guys acting like they know some secret. They can't come out and say all this is in the chambering of your individual rifle and has little to do with the cartridges. The 223 and 5.56 were interchangeable until Govt went with heavier bullet and different twist. That's when all this started.

7.62 NATO & 308Win I've never had a problem with. I only would use Match for reloads. Back in 60s there were problems with using 7.62 NATO to form 243Win and other similar cartridges. Excessive pressure from not reaming necks of the heavier brass was main problem.

7.62 NATO & 308Win I've never had a problem with. I only would use Match for reloads. Back in 60s there were problems with using 7.62 NATO to form 243Win and other similar cartridges. Excessive pressure from not reaming necks of the heavier brass was main problem.

I am sorting a bucket of range brass, separating the .223 and 5.56 brass. I'm aware of the case wall thickness differences between the two, but does that thickness come into play when you are reloading ? Do you separate the brass ? Do you treat the two as one ? My loads and never "hot", and I load for plinking and Coyotes. Just need something to worry about.

Lake City brass uses harder brass and as you can see below it is above average in uniformity compared to Remington and Winchester.

I buy bulk once fired Lake City brass and pick up any Lake City 5.56 brass with crimped primers at the range. This makes sure it all is once fired and uniform.

Save $$ By Using Lake City 5.56x45mm Once-Fired GI Brass

Save $$ By Using Lake City 5.56x45mm Once-Fired GI Brass << Daily Bulletin

Accuracy Potential of Mil-Surp 5.56 Brass

"So, how accurate can previously-fired GI surplus brass be in a good National Match AR-15? Well, here a data point from many years ago that might be of interest. A High Power shooter who wrote for the late Precision Shooting magazine took a Bill Wylde-built AR match rifle to a registered Benchrest match. His first 5-round group ever fired in a BR match was officially measured at 0.231 at 200 hundred yards. This was fired in front of witnesses, while using a moving target backer that confirmed all five rounds were fired.

He recounted that his ammo was loaded progressively with factory 52gr match bullets and a spherical powder using mixed years of LC brass with no special preparation whatsoever. Obviously, this was exceptional. However, he had no difficulty obtaining consistent 0.5-0.6 MOA accuracy at 200 yards using LC brass and a generic practice load that was not tuned to his rifle."

Last edited:

Similar threads

- Replies

- 25

- Views

- 525