I shot my 629 For the first time at the range yesterday.

I shot 6 44 specials, then after one 44 mag there was a rub and the cylinder didn’t want to turn.

That was the only 44 I shot in it.

I took it home and gave it a good clean (I can’t remember if I had cleaned it well after I picked it up a few months ago) The cylinder turns fine now except for a very slight bit of resistance on one of the chambers.

Typically, in this situation, is it due to needing a clean or might there be other issues.

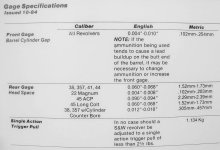

There is hardly any cylinder gap at all, and I know that there cannot be absolute zero gap.

I’m thinking of measuring the gap and possibly if necessary trimming the yoke a thou?

I can give it another good clean first.

Any suggestions??

Thanks

I shot 6 44 specials, then after one 44 mag there was a rub and the cylinder didn’t want to turn.

That was the only 44 I shot in it.

I took it home and gave it a good clean (I can’t remember if I had cleaned it well after I picked it up a few months ago) The cylinder turns fine now except for a very slight bit of resistance on one of the chambers.

Typically, in this situation, is it due to needing a clean or might there be other issues.

There is hardly any cylinder gap at all, and I know that there cannot be absolute zero gap.

I’m thinking of measuring the gap and possibly if necessary trimming the yoke a thou?

I can give it another good clean first.

Any suggestions??

Thanks