I have a S&W 32-20 with a badly pitted barrel. There are two deep holes in the upper right side of a 6" nickel barrel. They are about an inch apart, one behind the other with the first about an inch from the muzzle. Rifling is fair with scattered areas of roughness. Finding a replacement seems to be the search for the "Holy Grail". I have tried handloads with .312 and .313 diameter without much luck. My last trip to the range, I could not print on paper at 15yds. I took one of my good shooters and with the same ammo it did well. Will a cast bullet with a .314 diameter or heavy bullet ride past those pits? I'm thinking a heavier bullet may also help. Appreciated your thoughts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cast Bullet Diameter

- Thread starter delta-419

- Start date

Register to hide this ad

Bruce51

Member

The problem with a jacketed bullet and a light load is the bullet may get stuck in the barrel. Especially in a rough bore.

Anyway something I occassionally do just for fun is shoot round ball loads.

Hornady makes a 315" pure lead ball which weighs 47 grains.

Loaded with 2 grains of Bullseye powder for a gallery load of about 500 fps.

I seat the ball even with the case mouth and then put black powder lube into the gap between the ball and case.

Then a slight roll crimp is applied. The balls tend to group low on target.

Just thought that I would share this for members who have older revolvers looking for something different to try.

I tried this last week using 32 S&W cases in my Single Seven. Also works in a BH 30 carbine using the 310" round balls. Very accurate in the 1 in 20 twist.

Bruce

Anyway something I occassionally do just for fun is shoot round ball loads.

Hornady makes a 315" pure lead ball which weighs 47 grains.

Loaded with 2 grains of Bullseye powder for a gallery load of about 500 fps.

I seat the ball even with the case mouth and then put black powder lube into the gap between the ball and case.

Then a slight roll crimp is applied. The balls tend to group low on target.

Just thought that I would share this for members who have older revolvers looking for something different to try.

I tried this last week using 32 S&W cases in my Single Seven. Also works in a BH 30 carbine using the 310" round balls. Very accurate in the 1 in 20 twist.

Bruce

Ivan the Butcher

Member

The Ideal bullet mold 3118 (also 3117) was made for 32-20. It is 115 grains +/- and RBFP. Mine is a modern version for a gas check.. I size mine to .309, .311. and .314 for different uses. I always load 32-20 with .314". because rifling challenged guns need all the help they can get.

I see commercial RNFP bullets in 85/90, 105 and 115 grain weights, but you'll want the longer bullet for the extra bearing surface.

I use my cast bullets in 32 S&W Long (32 New Police), 30 Carbine, 30 Mauser, 32-20, 303 Savage, 300 Savage, 308 Win, 30-06 Spring., 30-30 light loads, 7.62x39, 7.62x54R, 303 British and a few oddballs for plinking rounds. Perhaps the most versatile mold made!

Ivan

I see commercial RNFP bullets in 85/90, 105 and 115 grain weights, but you'll want the longer bullet for the extra bearing surface.

I use my cast bullets in 32 S&W Long (32 New Police), 30 Carbine, 30 Mauser, 32-20, 303 Savage, 300 Savage, 308 Win, 30-06 Spring., 30-30 light loads, 7.62x39, 7.62x54R, 303 British and a few oddballs for plinking rounds. Perhaps the most versatile mold made!

Ivan

Midway has a 118gr gc LTB sized to.314 you could try. I have a high wall with an absolute garbage bore. At 25 yards everything lead keyholes into an 18in group. 100gr xtp's shoot 2-3 inches a 100yards. I can send you some of the 118gc to try if you'd like.

Did you slug the bore?

Nobody can provide an educated answer without that information.

Nobody can provide an educated answer without that information.

Besides barre diameter, a slug may give some indication of what's going on in the barrel...

SGT ROCK 11B

Member

... My last trip to the range, I could not print on paper at 15yds.

Appreciated your thoughts.

Move the Target closer.

sourdough44

Member

I would try your .314" idea, keeping expectations modest.

max503

Member

I'm a big fan of light loads. Just wondering why you don't use Lee Liquid Alox?The problem with a jacketed bullet and a light load is the bullet may get stuck in the barrel. Especially in a rough bore.

Anyway something I occassionally do just for fun is shoot round ball loads.

Hornady makes a 315" pure lead ball which weighs 47 grains.

Loaded with 2 grains of Bullseye powder for a gallery load of about 500 fps.

I seat the ball even with the case mouth and then put black powder lube into the gap between the ball and case.

Then a slight roll crimp is applied. The balls tend to group low on target.

Just thought that I would share this for members who have older revolvers looking for something different to try.

I tried this last week using 32 S&W cases in my Single Seven. Also works in a BH 30 carbine using the 310" round balls. Very accurate in the 1 in 20 twist.

Bruce

FWIW my Glocks (a 42 and a 26) are tack drivers with light charges of Bullseye and the Lee 100 grain Round Nose Flat Point.

Last edited:

gwpercle

Member

I would try two things :

1. Polish the rough bore with a brass brush , wrapped with 0000 steel wool and smeared with J-B Bore Compound ... a mild abrasive used to remove rust and fouling in gun barrels .

Polish untill everything looks as smooth as it's going to get ...

2. Hollow Based bullets ... like HBWC , but the nose shape doesn't matter ... the hollow base flares out to fit the barrel ...

Maybe try some hollow based plated or coated bullets ...

conventional lubed lead bullets don't do well with rough pitted barrels ... But you never know till you try ... standard lead hollow based wadcutter's may be just the ticket ... if the barrel is smooth enough .

Good Luck

Gary

1. Polish the rough bore with a brass brush , wrapped with 0000 steel wool and smeared with J-B Bore Compound ... a mild abrasive used to remove rust and fouling in gun barrels .

Polish untill everything looks as smooth as it's going to get ...

2. Hollow Based bullets ... like HBWC , but the nose shape doesn't matter ... the hollow base flares out to fit the barrel ...

Maybe try some hollow based plated or coated bullets ...

conventional lubed lead bullets don't do well with rough pitted barrels ... But you never know till you try ... standard lead hollow based wadcutter's may be just the ticket ... if the barrel is smooth enough .

Good Luck

Gary

OP

Slugged The Bore

I went back to the drawing board and addressed the issues with this very old 32-20 with your suggestions of how to seek remedies' to its poor performance. Number one was to do a vigorous cleaning of the bore with a wad of 4-O steel wool with oil followed by a stiff brass bore brush and machine oil. It looked better! Next was to slug the barrel with a diameter .313 cast lead bullet weighing 115gr. I was surprised to see grooves on all sides of the slug. The grooves looked shallow in the barrel but were highlighted on the slug itself (see photos). I changed out the trigger with one that gave me a better control of the firing sequence in SA at 4#s. I hope that this effort resolves some of these issues, only a range visit will show some life left in this old shooter.

I went back to the drawing board and addressed the issues with this very old 32-20 with your suggestions of how to seek remedies' to its poor performance. Number one was to do a vigorous cleaning of the bore with a wad of 4-O steel wool with oil followed by a stiff brass bore brush and machine oil. It looked better! Next was to slug the barrel with a diameter .313 cast lead bullet weighing 115gr. I was surprised to see grooves on all sides of the slug. The grooves looked shallow in the barrel but were highlighted on the slug itself (see photos). I changed out the trigger with one that gave me a better control of the firing sequence in SA at 4#s. I hope that this effort resolves some of these issues, only a range visit will show some life left in this old shooter.

Attachments

Bruce51

Member

let us know how this all works out.

To answer Max 503 question on Alox for lube. Yes it would be ok at such low velocities.

The bearing surface of a round ball is so small I rather have the lube in front of the ball.

Must be from shooting BP revolvers where the lube is used last to lube and seal the chamber.

Still trying out ideas such as placing a piece of cardboard over the lubed ball.

Bruce

To answer Max 503 question on Alox for lube. Yes it would be ok at such low velocities.

The bearing surface of a round ball is so small I rather have the lube in front of the ball.

Must be from shooting BP revolvers where the lube is used last to lube and seal the chamber.

Still trying out ideas such as placing a piece of cardboard over the lubed ball.

Bruce

Pits are not the problem.

The lands need to be high enough, to spin the bullet and

the bullet should fit the barrel for best results, in a clean barrel.

Good luck.

The lands need to be high enough, to spin the bullet and

the bullet should fit the barrel for best results, in a clean barrel.

Good luck.

I'd be taking a hard look at the cylinder, more specifically the throats in the chambers.

You need to take different sized bullets and push them thru each chamber in your cylinder. In a perfect world they are all the same size and 1/1000th's" larger then the bore of your bbl.

If they're smaller then the bbl it doesn't matter what you do. That revolver won't shoot a cast bullet unless you use a hollow based bullet.

If they are different sizes it will affect accuracy.

FWIW:

I've cast my own bullets and 99%+ of all my shooting needs (revolver/pistol/rifle) are done with cast/lead bullets since the 1980's. I have yet to slug any bbl in 40+ years and +/- 100 different firearms.

Leade's in the chambers yes, barrels no.

You need to take different sized bullets and push them thru each chamber in your cylinder. In a perfect world they are all the same size and 1/1000th's" larger then the bore of your bbl.

If they're smaller then the bbl it doesn't matter what you do. That revolver won't shoot a cast bullet unless you use a hollow based bullet.

If they are different sizes it will affect accuracy.

FWIW:

I've cast my own bullets and 99%+ of all my shooting needs (revolver/pistol/rifle) are done with cast/lead bullets since the 1980's. I have yet to slug any bbl in 40+ years and +/- 100 different firearms.

Leade's in the chambers yes, barrels no.

OP

Success

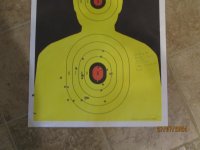

I took the 32-20 to the range yesterday with 40 rounds of fresh reloads using ,313 diameter cast led bullets over a light load of HP-38 for a 115gr bullet. The barrel had received an aggressive cleaning using a wad of 4-0 steel wool soaked in 3in1 oil, followed by a through stiff brass brush. In addition to the cleaning I replaced the hard trigger with one that broke much softer. I used two guns in this test firing, a proven vintage 32-20 as a control and the subject S&W. The control target results are on the right with the left target being from the problem gun. Targets were at 10 yards. The results were a very significant improvement. This old gun is a keeper! Thanks for all of your input.

I took the 32-20 to the range yesterday with 40 rounds of fresh reloads using ,313 diameter cast led bullets over a light load of HP-38 for a 115gr bullet. The barrel had received an aggressive cleaning using a wad of 4-0 steel wool soaked in 3in1 oil, followed by a through stiff brass brush. In addition to the cleaning I replaced the hard trigger with one that broke much softer. I used two guns in this test firing, a proven vintage 32-20 as a control and the subject S&W. The control target results are on the right with the left target being from the problem gun. Targets were at 10 yards. The results were a very significant improvement. This old gun is a keeper! Thanks for all of your input.

Attachments

Last edited:

Similar threads

- Replies

- 7

- Views

- 778

- Replies

- 2

- Views

- 721

- Replies

- 26

- Views

- 2K