In my experience most people tend to think in absolute terms. In the real world there will always be variances in dimensions due to manufacturing methods, tooling, and materials in use.

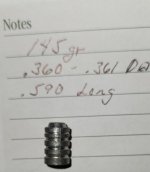

Cast bullets measuring .360-.361" are not unusual, depending on the mold in use and the lead alloy used in production. The common method for dealing with these minor differences is by sizing the bullets, essentially swaging them down to a dimension closer to the desired result. Even then, we are dealing with sizing dies and equipment that will display manufacturing tolerances, further complicated by the composition of the cast bullets (different alloys will respond to sizing differently, with harder alloys tending to display more "spring-back" effect after the sizing operation).

Softer lead alloys tend to shrink more while solidifying in the mold than harder alloys, and both will show varying degrees of sizing effect when run through the same sizing dies.

One likely explanation for the OP's current experience is bullets cast in a mold designed to produce a bullet of nominal .358-.359" bullet with a specific lead alloy (such as Lyman #2, relatively soft lead-tin mixture), but used to cast bullets with a harder metal such as wheel-weights or type metals. Another factor supporting this hypothesis is the reported weight of 145 grains, which is 3 grains lighter than the nominal standard of 148 grains (explained easily by the lighter results obtained when using harder alloys).

It took me quite a while to grasp the concepts of "nominal dimensions", manufacturing tolerances, and all the other variables involved in every aspect of firearms and reloading.