OP

- Joined

- Aug 21, 2024

- Messages

- 91

- Reaction score

- 77

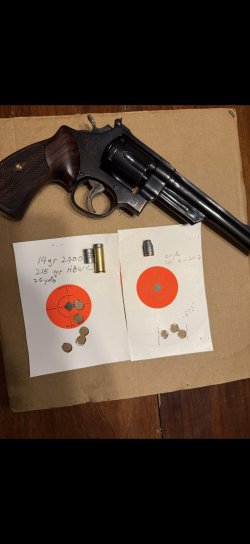

I wanted to tell everyone thankyou for the tips, Help, etc. with my 24-3 Cast bullet Accuracy project.

I got the Mihec- 215 gr. HBWC Thanks to a recommendation from Forrest R, I already had the Lee 240 Grain GC. Rock quarry sent me a few bullets to check proper fit and I ended up casting, powder coating, then sizing both bullets .431" which is snug in the cylinder. I couldn't get a .432 sizer,

I have tried a couple diff charges of 2400 and HS-6, both look like I have something I can work with, I hav'nt Sorted brass headstamps, Trimmed brass uniform length, or Sorted bullets by weight (yet). I am encouraged by results I have at 25yds (from a rest) with just 2 range sessions and a handful of loads tried. The trigger is about 3.5lbs I would much rather 2.75-3, Any way I'm really liking the 24-3. Again Thanks to everyone that offered advise.

I got the Mihec- 215 gr. HBWC Thanks to a recommendation from Forrest R, I already had the Lee 240 Grain GC. Rock quarry sent me a few bullets to check proper fit and I ended up casting, powder coating, then sizing both bullets .431" which is snug in the cylinder. I couldn't get a .432 sizer,

I have tried a couple diff charges of 2400 and HS-6, both look like I have something I can work with, I hav'nt Sorted brass headstamps, Trimmed brass uniform length, or Sorted bullets by weight (yet). I am encouraged by results I have at 25yds (from a rest) with just 2 range sessions and a handful of loads tried. The trigger is about 3.5lbs I would much rather 2.75-3, Any way I'm really liking the 24-3. Again Thanks to everyone that offered advise.