At this point, I've put almost 2K rounds of .22 LR through my dead air mask .22 suppressor and several hundred, but probably less than 1K through my rugged obsidian .45. I had been noticing a degradation in suppression and mrs tlawler even mentioned that the mask wasn't as quiet as it was when new and I first started shooting in my garage range.

I watched a couple of youtube videos on disassembly and was able to get the baffles out of the tubes with a little persuasion with appropriately sized wooden dowels and a rubber mallet. I was amazed at how dirty the .22 suppressor was, and the .45, while pretty dirty, wasn't anywhere near as bad as the .22. It literally had lead plated out on the baffles that would not come off with basic wire brushing.

I did a search for methods of lead removal and found out about something called "the dip". It's a simple mixture of hydrogen peroxide and white vinegar that reacts with the lead to turn it into lead acetate in liquid form, so proper PPE and approved disposal methods are essential.

It still took several dips, with a lot of wire brushing and scraping with a pick between dips to get everything off. I then ran the baffles through my Lyman wet tumbler with pins for 2 hours.

All of my baffles are now squeaky clean and ready to reassemble. I also discovered another process that I'm going to do that involves heating the baffles to 300 degrees and quenching in silicone oil that will make them less susceptible to lead plating. I'll report how that goes after amazon delivers my silicon oil early next week.

I'd like to get the thoughts of others that have more experience with suppressors and cleaning them to see what you think of my methods. Have you tried them? Do you have other methods? I am hoping that with the silicone oil treatment and more frequent cleaning (never going 2K rounds between cleanings!), I'll be able to use the ultrasonic cleaner and simple green method.

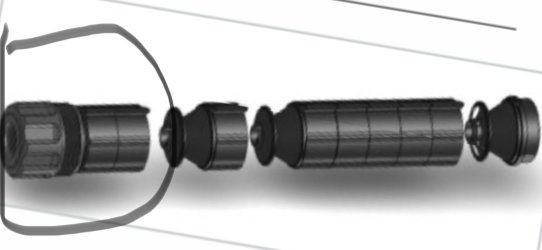

I didn't take a before picture ( I wish I had), but here is a picture of my results.

I watched a couple of youtube videos on disassembly and was able to get the baffles out of the tubes with a little persuasion with appropriately sized wooden dowels and a rubber mallet. I was amazed at how dirty the .22 suppressor was, and the .45, while pretty dirty, wasn't anywhere near as bad as the .22. It literally had lead plated out on the baffles that would not come off with basic wire brushing.

I did a search for methods of lead removal and found out about something called "the dip". It's a simple mixture of hydrogen peroxide and white vinegar that reacts with the lead to turn it into lead acetate in liquid form, so proper PPE and approved disposal methods are essential.

It still took several dips, with a lot of wire brushing and scraping with a pick between dips to get everything off. I then ran the baffles through my Lyman wet tumbler with pins for 2 hours.

All of my baffles are now squeaky clean and ready to reassemble. I also discovered another process that I'm going to do that involves heating the baffles to 300 degrees and quenching in silicone oil that will make them less susceptible to lead plating. I'll report how that goes after amazon delivers my silicon oil early next week.

I'd like to get the thoughts of others that have more experience with suppressors and cleaning them to see what you think of my methods. Have you tried them? Do you have other methods? I am hoping that with the silicone oil treatment and more frequent cleaning (never going 2K rounds between cleanings!), I'll be able to use the ultrasonic cleaner and simple green method.

I didn't take a before picture ( I wish I had), but here is a picture of my results.