I apologize for my delayed return to this thread. Family illness and a pistol tournament down in Phoenix got in the way. I was finally able to test the 686-6 for accuracy in my Ransom Rest. Following warmup shots from all cylinders, I fired five consecutive five shot groups at 25 yards on the same multi bullseye target. I moved the target between each group so as not to disturb the Rest. I used 357 cases with a slightly increased powder charge, selected using QuickLOAD, in an effort to duplicate the performance of my standard 38 special bullseye ammunition. The average group size was 1.90 inches. The average velocity was 734 fps, standard deviation was 25 fps.

For reference, I can report that my model 67-5 shoots 1.26 inch average groups with my standard 38 special bullseye ammunition under the same test conditions. I have recorded average velocity at 750 fps, standard deviation at 24 fps.

About 50 rounds had been fired in the 686 by the end of this testing. Limited leading was present in the barrel beyond the forcing cone. For comparison, my model 67 showed less leading after firing about 180 rounds in the centerfire stages of Phoenix match.

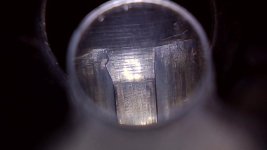

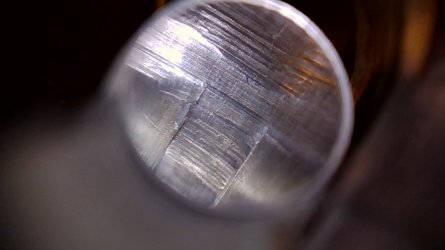

I also slugged the barrel and each cylinder throat on the 686. I used round Hornady lead balls driven into clean lubricated throats and barrel. To be sure I get accurate readings, I bump up the resulting lead slugs after they are in place. The cylinders were very consistent at .3576. The barrel minimum groove dimension was .3552. The barrel was tight at this minimum at the muzzle and at a point just forward of the forcing cone. Between these two locations the barrel was loose on the slug. I did not push the barrel slug over the burrs at the forcing cone.

My plan now will be to fire full power jacketed 357 ammunition to see if the burrs can be worn away. If this works, I will repeat the accuracy testing with bullseye ammunition.

For reference, I can report that my model 67-5 shoots 1.26 inch average groups with my standard 38 special bullseye ammunition under the same test conditions. I have recorded average velocity at 750 fps, standard deviation at 24 fps.

About 50 rounds had been fired in the 686 by the end of this testing. Limited leading was present in the barrel beyond the forcing cone. For comparison, my model 67 showed less leading after firing about 180 rounds in the centerfire stages of Phoenix match.

I also slugged the barrel and each cylinder throat on the 686. I used round Hornady lead balls driven into clean lubricated throats and barrel. To be sure I get accurate readings, I bump up the resulting lead slugs after they are in place. The cylinders were very consistent at .3576. The barrel minimum groove dimension was .3552. The barrel was tight at this minimum at the muzzle and at a point just forward of the forcing cone. Between these two locations the barrel was loose on the slug. I did not push the barrel slug over the burrs at the forcing cone.

My plan now will be to fire full power jacketed 357 ammunition to see if the burrs can be worn away. If this works, I will repeat the accuracy testing with bullseye ammunition.