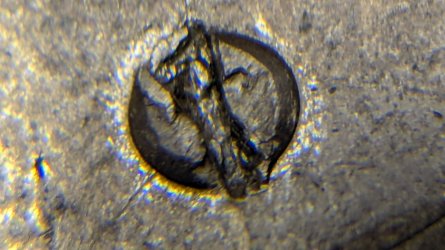

Not sure if this would be the correct section for this thread, if not please let me know where to post it. This revolver has been in my family for over 7 decades. Up until the mid 1990's it would function. Suddenly the hammer would release with the slightest bump, also the trigger would not fully reset without assistance. That's when I put it up until recently. I want to try my luck and getting functional once again and redo the toasted nickel finish. Someone before it came into my family attempted to remove the side plate screw and the pivot screw. The side plate screw is severely damaged and I'm taking my time trying to remove it the best I can. I've hit them both with P B Blaster for the last 2 days hoping it gets in there and helps break the threads free. Due to the amount of damage I'm sure I'll be searching for a replacement. I do not think there is enough value in this to take it to a seasoned gunsmith. I want to learn so it is my test subject. Any recommendations on getting this screw out? One of my initial thoughts is to use a very tiny grinding bit in my dremel to establish a solid groove for the straight slot bit to grab without doing what has already been done. I don't have easy outs (at least not yet) but trying to work with what I already have if it seems logical.

The serial number is 61115

The serial number is 61115