M5741

Member

Newby here, and I say HEY to all members here on this great forum. I've been lurk'n around for a while and finally decided to dive right in.

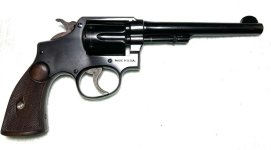

I purchased a 1905 5 screw in 32-20 WCF a few days ago at one of the local pawn shops. I've never even picked up one of these revolvers before in my life. It absolutely felt great when I wrapped my mitts around the grips. I figured that was the best reason for buying it, yes? Serial number is 943xx. Im guessing its about a 1922 issue. It has a 5" barrell and is a blued model. Grips are wood, with no medallions. There is very very light speckled pitting on the surface. I disassembled to clean, and as suspected, dried on lubricant. The hammer was absolutely brutal to pull to the full cock position. I was hoping a good cleaning would solve that issue. I found some parts that

need replaced. The center pin has a slight bend where it protrudes out of the ejecter star, and is worn on one side where it goes into the recoil sheild. Also, the cylinder stop is worn where the nubbin protrudes above the frame to engage the cylinder. Question No.1: The original cylinder stop in the revolver has a spring and plunger that pushes on a radiused corner of the stop. The cylinder stops that are on line, have a hole in them where only a spring is used to push with. Can that cylinder stop be used to replace of the original? After cleaning and lubricating, the hammer pull did get smoother. But it is still very hard to pull to full cock position. No.2: Is it normal for these revolvers to have such a hard hammer pull. I have other revolvers, and don't have any problem pulling back the hammers.

Sorry for the first time long post. Regards

I purchased a 1905 5 screw in 32-20 WCF a few days ago at one of the local pawn shops. I've never even picked up one of these revolvers before in my life. It absolutely felt great when I wrapped my mitts around the grips. I figured that was the best reason for buying it, yes? Serial number is 943xx. Im guessing its about a 1922 issue. It has a 5" barrell and is a blued model. Grips are wood, with no medallions. There is very very light speckled pitting on the surface. I disassembled to clean, and as suspected, dried on lubricant. The hammer was absolutely brutal to pull to the full cock position. I was hoping a good cleaning would solve that issue. I found some parts that

need replaced. The center pin has a slight bend where it protrudes out of the ejecter star, and is worn on one side where it goes into the recoil sheild. Also, the cylinder stop is worn where the nubbin protrudes above the frame to engage the cylinder. Question No.1: The original cylinder stop in the revolver has a spring and plunger that pushes on a radiused corner of the stop. The cylinder stops that are on line, have a hole in them where only a spring is used to push with. Can that cylinder stop be used to replace of the original? After cleaning and lubricating, the hammer pull did get smoother. But it is still very hard to pull to full cock position. No.2: Is it normal for these revolvers to have such a hard hammer pull. I have other revolvers, and don't have any problem pulling back the hammers.

Sorry for the first time long post. Regards

Last edited: