rhodesengr

Member

- Joined

- Jul 12, 2021

- Messages

- 133

- Reaction score

- 68

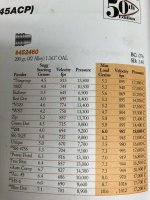

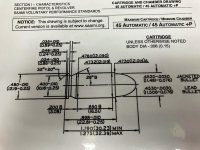

I've been loading 45ACP with ZERO 230gr JHP bullets but wanted to try 200gr LSWC. I looked up the loads for AA#5 and it calls for a COL of 1.190 which seems insanely short. That will put the case mouth above the bullet shoulder. Is that really the way it's supposed to be? Or maybe the bullet used in the listed load has a longer base section? The COL of 1.190 is shown on both the Hodgdon website and Western Powder V8 (shown below). The loads I am referring to are for the LC 200gr SWC.

Same bullet (LC LSWC) with Silhouette is listed with a COL of 1.267. Seems like a huge difference for the same bullet. Seems like an odd coincidence the the numbers for the two powders 1.190 and 1.267 are also the SAMMI max and min COL's.

I was making my 230gr JHP at 1.210

The LSWC bullets I have are from Rim Rock. At 1.253 (photo below), there is still some lead above case. I did some plunk testing and the 1.253 COL plunked OK but seemed to have a little resistance to spinning. I've done some searching and found some other threads about this. I settled on 1.235 which still leaves some lead above the mouth but 1.190? Is that real?

Same bullet (LC LSWC) with Silhouette is listed with a COL of 1.267. Seems like a huge difference for the same bullet. Seems like an odd coincidence the the numbers for the two powders 1.190 and 1.267 are also the SAMMI max and min COL's.

I was making my 230gr JHP at 1.210

The LSWC bullets I have are from Rim Rock. At 1.253 (photo below), there is still some lead above case. I did some plunk testing and the 1.253 COL plunked OK but seemed to have a little resistance to spinning. I've done some searching and found some other threads about this. I settled on 1.235 which still leaves some lead above the mouth but 1.190? Is that real?