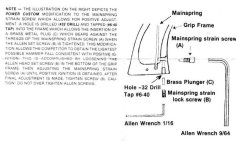

For various reasons, I wanted the ability to adjust the strain screw on the fly if I have to, but also have it locked. Here's a cheap solution which does not require drilling & tapping the frame and only requires a sacrificial Allen wrench and a 8-32 Allen head set screw.

Set your 8-32 Allen head strain screw and cut down the Allen wrench as shown in the pics. I also hammered the Allen wrench bend to be a bit flatter.

The attached Allen wrench prevents the strain screw from moving. I've shot over 1,000 rounds on this quick & dirty proof of concept version and it works as designed.

I tapered the long end of the Allen wrench in case it snagged on on my Hogue grips during installation. It didn't snag.

I taped over the wrench to check for any rubbing during grip installation. Nothing moved.

I installed & removed the Hogue grip 10 times with no problems. If I need to adjust it during a match I'll just peel off the tape, turn the screw and re-tape the Allen wrench.

Set your 8-32 Allen head strain screw and cut down the Allen wrench as shown in the pics. I also hammered the Allen wrench bend to be a bit flatter.

The attached Allen wrench prevents the strain screw from moving. I've shot over 1,000 rounds on this quick & dirty proof of concept version and it works as designed.

I tapered the long end of the Allen wrench in case it snagged on on my Hogue grips during installation. It didn't snag.

I taped over the wrench to check for any rubbing during grip installation. Nothing moved.

I installed & removed the Hogue grip 10 times with no problems. If I need to adjust it during a match I'll just peel off the tape, turn the screw and re-tape the Allen wrench.