Are we talking about an extractor or an ejector ? OP said ejector.Below are instructions from rimfire central.look at last sentence

you will have a difficult time finding a factory replacement ejector. Those have been out of production for decades. The Texas High Standard pistols do not use a separate part for the ejector. The ejector is milled into the top of the frame during the machining process. It is integral to the frame.

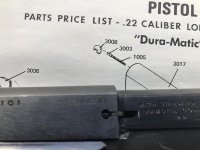

You can make a suitable ejector to fit into the angled hole in the frame on your gun. Use the shank of a 1/8" drill bit, and cut the piece to about 0.6" length. This will fit into the hole and protrude high enough above the frame so that the upper end can be machined to form the ejector. The top of the ejector should be is parallel to the frame, and the sides of the part narrowed to fit the slide. The part should fit about 0.125" above the frame, and the each of the sides machined to leave the ejector portion about 0.060" wide. You will probably have to convert these dimensions to metric. I used a Dremel tool with appropriate grinding and cutting bits to form the top of the ejector on one I replaced in a pistol.

Use red Loctite or similar material to affix the part into the hole. Please note that the original ejector shaft was splined and pressed into the hole.