Hi There,

"This part is under high stress when ejecting spent, dirty casings. It broke not from age but abuse by whomever years ago muscled a dirty gun open with stuck shells."

Interesting theory but I think the break is from a different cause

and I'll explain why.

First, the frame (which is iron) is softer than the hardened steel

of the catch. If the break was from the stress you describe, the

hole in the frame where the "tail" of the catch fits into, would

show signs of the shear forces that would have snapped the tail.

There is no evidence of this.

Second, the break of the tail is at a point where the tail is inside

the hole in the frame where it should have been supported. This

is the reason I didn't notice it before. I've never removed the

barrel before until now and therefore couldn't see it.

Of course, you didn't have access to see these things so you

couldn't know. Upon closer scrutiny, I think I see what hap-

pened. The catch had a flaw as a result of its manufacture.

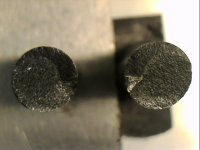

There is a distinct difference in the grain structure of the steel

that can be seen when magnified. This left the part with a pre-

disposition to break at this point. Take a look at the pic.

There is a section that is darker and looks (to me) to have a

finer grain structure. The rest is lighter colored and looks to

have a courser grain and was probably part of a micro-crack

or fissure that weakened the catch and made it break. If I'm

correct, this part would break with very little shear stress applied.

Reading about the U.S. Army No. 3 Americans and the parts

that broke while in service tells me there was a considerable

amount of faulty heat-treating happening at the time and was

one of the reasons the Army decided not to purchase any more

No. 3's (until the Schofield model).

I don't know anything about "micro welding" but high carbon

steel doesn't behave well when welded. The forces created by

the metal contracting as it cools can cause other areas adjacent

to the weld to crack. One can try to use pre and post heating

to minimize some of the stresses but then one runs the risk of

destroying the grain structure in the steel and it will become

brittle somewhere else (or even everywhere else). I don't want

to ruin this part.

Cheers!

Webb