Hi Gents

I am restoring an early SW Russian in 44 Russian which is missing some parts including the ejector star and parts of the ejector cam mechanism that engages the rings on the ejector rod mechanism.

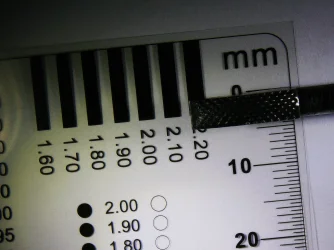

Unlike the other Russians I own, this one does not appear to use the spring loaded pivoting ejector lever which engages with the ejector cam as you break the pistol open to eject the cartridges. Instead there is small hole in the frame between the 2 lobes of the barrel pivot point which looks like some sort of a spring loaded pin would have sat in there like a piston to engage the ejector cam . I have not been able to find a diagram or schematic anywhere of this alternative mechanism for engaging the cam to provide the spring pressure which opposes and engages the ejector rod . If anyone has an exemplar or can share this information it would be greatly appreciated, I can likely fabricate it in my shop but an accurate dimension diagram or even a photo with scale would be a huge help. I have attached a shot of the frame with an adjacent frame from a regular Russian to show the difference in the pivoting ejector lever vs unknown mechanism. If anyone has these parts and would like to sell them that would be even better but that's likely Unobtainium in the periodic table of gun parts.

This pistols 7 inch barrel was marked:

Smith&Wesson Springfield. Mass. U.S.A. Pat July 16 60 Jan 17 Feb 17 July 11 65&Aug 24 69 Russian Model 1 ( 1 or perhaps +, cant tell as faint)

No expert but from what I can glean this would be the SW No 3 second model or "Old old Model Russian"?

In the photo you can barely see in the left hand frame the tiny hole versus the pivot ejector lever in the same location in the more normal frame on the right.

Any advice greatly appreciated.

I am restoring an early SW Russian in 44 Russian which is missing some parts including the ejector star and parts of the ejector cam mechanism that engages the rings on the ejector rod mechanism.

Unlike the other Russians I own, this one does not appear to use the spring loaded pivoting ejector lever which engages with the ejector cam as you break the pistol open to eject the cartridges. Instead there is small hole in the frame between the 2 lobes of the barrel pivot point which looks like some sort of a spring loaded pin would have sat in there like a piston to engage the ejector cam . I have not been able to find a diagram or schematic anywhere of this alternative mechanism for engaging the cam to provide the spring pressure which opposes and engages the ejector rod . If anyone has an exemplar or can share this information it would be greatly appreciated, I can likely fabricate it in my shop but an accurate dimension diagram or even a photo with scale would be a huge help. I have attached a shot of the frame with an adjacent frame from a regular Russian to show the difference in the pivoting ejector lever vs unknown mechanism. If anyone has these parts and would like to sell them that would be even better but that's likely Unobtainium in the periodic table of gun parts.

This pistols 7 inch barrel was marked:

Smith&Wesson Springfield. Mass. U.S.A. Pat July 16 60 Jan 17 Feb 17 July 11 65&Aug 24 69 Russian Model 1 ( 1 or perhaps +, cant tell as faint)

No expert but from what I can glean this would be the SW No 3 second model or "Old old Model Russian"?

In the photo you can barely see in the left hand frame the tiny hole versus the pivot ejector lever in the same location in the more normal frame on the right.

Any advice greatly appreciated.