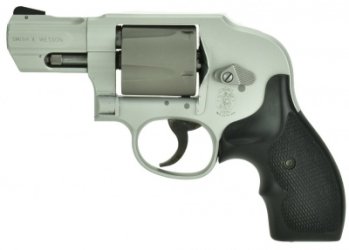

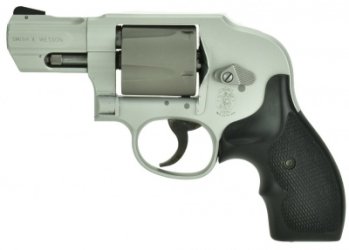

Is there any issue with more top level SAAMI loads in a S&W 296 Ti (44 Special) with the titanium cylinders? What I am curious about is erosion of the titanium cylinders in the flame gap area, potential for flame cutting of the aluminum frame (no stainless guard like a 340 PD), or sticky extraction.

Sure, the 44 Special is a low pressure load and no where even close to the 357 magnum even when loaded hotter by Buffalo Bore or Underwood, so I find it interesting in the 44 Special video with Tim Sundles from Buffalo Bore where he mentions sticky extraction in the 296 Ti with some of the heavier 44 Special loads and no mention of sticky extraction in the 396 (same frame size and material as 296), so it makes me wonder what the guidance should be regarding proper ammo selection and limits for the 296 Ti. The 340 PD has a titanium cylinder and is 357 Magnum and I have not heard of sticky extraction in that either.

On thing that is interesting is how thin the barrel is at the forcing cone on a 296 Ti and how thin the cylinder wall is.

Sure, the 44 Special is a low pressure load and no where even close to the 357 magnum even when loaded hotter by Buffalo Bore or Underwood, so I find it interesting in the 44 Special video with Tim Sundles from Buffalo Bore where he mentions sticky extraction in the 296 Ti with some of the heavier 44 Special loads and no mention of sticky extraction in the 396 (same frame size and material as 296), so it makes me wonder what the guidance should be regarding proper ammo selection and limits for the 296 Ti. The 340 PD has a titanium cylinder and is 357 Magnum and I have not heard of sticky extraction in that either.

On thing that is interesting is how thin the barrel is at the forcing cone on a 296 Ti and how thin the cylinder wall is.