You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

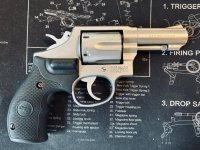

Weird finish on S&W Model 10

- Thread starter vijonesjr

- Start date

Register to hide this ad

OutAtTheEdge

Member

Looks like electroless nickel to me. (I could be wrong, it happened once before...)

Birdhunter6

Member

Electroless nickel was a popular refinish option back in the day.

- Joined

- Jun 28, 2007

- Messages

- 27,669

- Reaction score

- 21,362

Several possibilities - satin nickel as noted above, bead blasted original finish (although this might remove the plating), hard chrome or a baked on finish like Cerakote. Hard to say without an in-person look.

I'd wager it's a refinish, to me it looks like it was blasted with aluminum oxide, then plated with electroless nickel. Electroless nickel can be a very good finish for a firearm, big question would be as to why it was refinished. Any sign of pitting? Such finishes are often applied to firearms that were neglected and became rust pitted. It could also be that someone wanted a corrosion resistant finish, but had a blued Model 10 and did want to trade for a factory nickel plated Model 10 or did not like the highly polished finish of the factory plating.

- Joined

- Feb 25, 2014

- Messages

- 1,815

- Reaction score

- 3,638

I may be way off but to me it looks like it was sprayed with Cerakote.

Look how it fills in the S&W emblem on the side plate.

Look how it fills in the S&W emblem on the side plate.

I think anytime you bead blast or Cerekote it's because the original finish had pitting and flecking. Why else would u do it?

Smolt Smython

Member

that's, uh......pretty "frosty" looking....

Ivan the Butcher

Member

My 49 no dash has been refinished and looks very similar. in the 80's, a popular refinish was "Metal Life". It is a Teflon coating and came in many colors. When done properly, the action will be as smooth a butter. When done wrong, the action will be near impossible to "Ungunk" it!

Back in those days, this kind of refinish was about $35 retail. Almost 40 years later and mine is still going strong. From the pictures, it looks lie a nice job.

Some will say the gun is ruined. Not at all! The museum quality collectors value was most likely already gone, and these are great "Shooter" grade guns.

Ivan

Back in those days, this kind of refinish was about $35 retail. Almost 40 years later and mine is still going strong. From the pictures, it looks lie a nice job.

Some will say the gun is ruined. Not at all! The museum quality collectors value was most likely already gone, and these are great "Shooter" grade guns.

Ivan

I'm pretty sure Smith and Wesson never offered an e-nickel or hard chrome finish as a factory finish but other companies did. I bought a Colt 1911 that was in EN from the factory about 1980 or so. That thing looked sharp with it's black Pachmayr/Colt wrap around grips.

- Joined

- Jun 28, 2007

- Messages

- 27,669

- Reaction score

- 21,362

My 49 no dash has been refinished and looks very similar. in the 80's, a popular refinish was "Metal Life". It is a Teflon coating and came in many colors. When done properly, the action will be as smooth a butter. When done wrong, the action will be near impossible to "Ungunk" it!

Back in those days, this kind of refinish was about $35 retail. Almost 40 years later and mine is still going strong. From the pictures, it looks lie a nice job.

Some will say the gun is ruined. Not at all! The museum quality collectors value was most likely already gone, and these are great "Shooter" grade guns.

Ivan

The original Metalife owner and company are still around, been considering sending one of mine for the treatment.

Wyatt Burp

Member

It resembles the Electroless finish on my 1980 Python which might have been done for Colt by a Texas company called Nitex. Run by a guy named Ed House. In an early 70s G&A Annual I have there was another company who did this.

Bead blasting can be/produce virtually any sort of finish/surface you can imagine. My experience with it is confined to cleaning internal engine parts on the one hand with glass bead peening---and what started out as a wild hair idea to improve lubrication retention of tappets (valve lifters). These tappets had a very hard bearing surface on the one hand----but didn't last very long on the other hand. I decided they'd last longer if they retained more oil on the bearing surface---so I roughed up the surface with glass bead peening---and damned if it didn't work!

Bead blasting does/can do all sorts of things depending upon the media (the beads)---what they're made out of----steel/glass/sand/crushed walnut shells/you name it)-----the size-----and the material being blasted----and the line pressure-----and the angle of attack. The folks who know what they're doing (the real artists) can accomplish all sorts of things beyond just the external appearance.

I had a mega-buck Master Grade conversion of a 1911 from Wilson Combat---speaking of external appearance. The frame was plated with white metal of some sort, and the slide was blued. The surfaces of both had been prepped by peening----with whatever media---by someone who REALLY knew what they were doing! It made for a drop-dead GORGEOUS finish on both!!

If/when you ask these artists how they did that, they just smile, and say "Very carefully!"

Ralph Tremaine

Bead blasting does/can do all sorts of things depending upon the media (the beads)---what they're made out of----steel/glass/sand/crushed walnut shells/you name it)-----the size-----and the material being blasted----and the line pressure-----and the angle of attack. The folks who know what they're doing (the real artists) can accomplish all sorts of things beyond just the external appearance.

I had a mega-buck Master Grade conversion of a 1911 from Wilson Combat---speaking of external appearance. The frame was plated with white metal of some sort, and the slide was blued. The surfaces of both had been prepped by peening----with whatever media---by someone who REALLY knew what they were doing! It made for a drop-dead GORGEOUS finish on both!!

If/when you ask these artists how they did that, they just smile, and say "Very carefully!"

Ralph Tremaine

Last edited:

That's been hit with some pretty heavy duty grit. More like a 'sand' blast than a bead blast. But as said above, there are so many variables with grit material, size, air pressure, etc, there are a lot of effects possible with someone that really understands what they are doing.

Looks like they have left the inside of the TG a smooth brite polish for some contrast. Maybe it's just the pic.

In a shop I worked in at one time used to take trade-in guns that were in less than desireable finish condition and simply mark them 'BBB' on a tag and send them back to the gunsmiths area.

BBB was for Bead Blast & Blue.

A quick way to refinish w/o doing any polishing at all. It covered many scatches and marks and made a much more sellable gun to put on the rack. Not much time invested.

On some era Win70's we'd use what they called 'rocks' to blast the recv'rs. A fine grain sand and low pressure. It looked closer to the orig Winchester type finish but that's all you could say about it!

Some of the real bad condition other guns got the rock treatment as well', but you can ony hide so much.

Looks like they have left the inside of the TG a smooth brite polish for some contrast. Maybe it's just the pic.

In a shop I worked in at one time used to take trade-in guns that were in less than desireable finish condition and simply mark them 'BBB' on a tag and send them back to the gunsmiths area.

BBB was for Bead Blast & Blue.

A quick way to refinish w/o doing any polishing at all. It covered many scatches and marks and made a much more sellable gun to put on the rack. Not much time invested.

On some era Win70's we'd use what they called 'rocks' to blast the recv'rs. A fine grain sand and low pressure. It looked closer to the orig Winchester type finish but that's all you could say about it!

Some of the real bad condition other guns got the rock treatment as well', but you can ony hide so much.

Could it be Metaloy Hard Chrome?

Excellent finish and durable.

Excellent finish and durable.

Wyatt Burp

Member

I think Metaloy was the company I saw an article about in a 1973 or so Guns & Ammo Annual.Could it be Metaloy Hard Chrome?

Excellent finish and durable.

Similar threads

Sold/Withdrawn

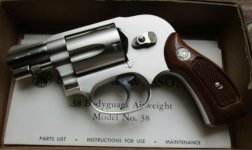

Beautiful Model 10 Nickel Snub

- Replies

- 1

- Views

- 776

- Locked

Sold/Withdrawn

S&W model 10-8, factory nickel, 3" barrel, round butt

- Replies

- 1

- Views

- 350