2nd R/R Slugged

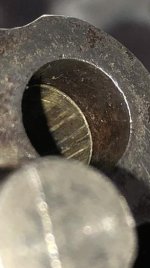

I slugged another R/R and found the same .323 groove diameter. You can see the .325 slug has perfect contact with both the lands and grooves of the bore. See photo

Also a photo of the rear Flip Sight. Both high and low settings.

Murph

I slugged another R/R and found the same .323 groove diameter. You can see the .325 slug has perfect contact with both the lands and grooves of the bore. See photo

Also a photo of the rear Flip Sight. Both high and low settings.

Murph

Attachments

Last edited: