Rachel33189

Member

- Joined

- Nov 22, 2011

- Messages

- 6

- Reaction score

- 13

I recently added a Model 66-8 to my collection. Looks and feels much like my 2-1/2 inch Model 19. First (and every) outing to the range I get anywhere from 18 to 30 shots out of the 66 before everything is jammed up tight. Rubber mallet tight.

Below are some close ups of the cylinder fore-ends and the rear of the barrels on both guns. The 19 has a nice, elevated gas ring that is shielded completely by a plate of sorts on the rear of the crane, and the rear of the barrel shows a flat cut on the bottom to allow the crane to close and lock up.

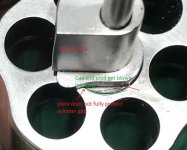

The 66 appears to have eliminated the gas ring and the rear of the crane has only a partial plate shielding the cylinder axis. This appears to have been done to eliminate the flat cut on the barrel but the problem here is that the recessed area sits directly under the rear of the barrel and every time the gun is fired the hot gases blow all sorts of junk right past the partial shield and deep inside the cylinder. No wonder it keeps jamming.

Unfortunately the model 66 requires complete disassembly of the cylinder after every outing. There has to be a better way!

Below are some close ups of the cylinder fore-ends and the rear of the barrels on both guns. The 19 has a nice, elevated gas ring that is shielded completely by a plate of sorts on the rear of the crane, and the rear of the barrel shows a flat cut on the bottom to allow the crane to close and lock up.

The 66 appears to have eliminated the gas ring and the rear of the crane has only a partial plate shielding the cylinder axis. This appears to have been done to eliminate the flat cut on the barrel but the problem here is that the recessed area sits directly under the rear of the barrel and every time the gun is fired the hot gases blow all sorts of junk right past the partial shield and deep inside the cylinder. No wonder it keeps jamming.

Unfortunately the model 66 requires complete disassembly of the cylinder after every outing. There has to be a better way!