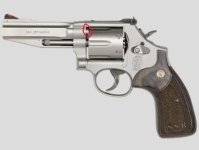

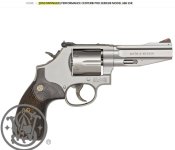

I just picked up a 686 SSR and went to clean & lube in preparation for a range trip. I found this sliver wedged between the barrel and frame (see the red circle). It looks to be a piece of brass about 3/16". Any thoughts members may have are welcome. Bertter picture added.

Attachments

Last edited: