You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A GOOD CASE FOR NOT DUPLICATING BUFFALO BORE'S 38 SPL. "FBI LOAD"

- Thread starter chief38

- Start date

jjmIII_Ruger

Member

Truth in advertising???

Buffalo Bore says that they don't exceed SAAMI specs. If they do and there is a kaboom, they have big time liability.

Quite honestly, I'm not that familiar with BB. I make do with the regular grade of gas. But everything is speculation as none of us know what BBs strategy is. Maybe they just count on modern guns having a big enough safety factor not to blow up, but beating your gun up over a short time is almost as bad.

I think they regularly exceed maximum pressure.

Buffalo Bore says that they don't exceed SAAMI specs. If they do and there is a kaboom, they have big time liability.

Quite honestly, I'm not that familiar with BB. I make do with the regular grade of gas. But everything is speculation as none of us know what BBs strategy is. Maybe they just count on modern guns having a big enough safety factor not to blow up, but beating your gun up over a short time is almost as bad.

Buffalo Bore has made a regular routine of shirking SAAMI so there isn't one good reason to expect that ANY particular Buffalo Bore product aligns with industry standards.

At the same time...

For a modern S&W, the only thing that makes sense from a manufacturing-for-profit standpoint is that their .38 revolvers and their .357 revolvers are made from the same steels and the same heat treating processes.

I am -NOT- advocating that handloaders should load beyond published guidelines. (however, the very skilled and connected those that DO benefit all of us, thank you Mr. Elmer Keith and your contemporaries) But a quality modern firearm can handle the stuff Buffalo Bore makes and can also handle the loads that a skilled handloader develops using established methods to attempt to replicate them.

As to the Blackhawk with a bulged chamber... far too little evidence to come to solid conclusions. A perfectly spec'd load could have bulged that chamber if there was a bore obstruction.

At the same time...

For a modern S&W, the only thing that makes sense from a manufacturing-for-profit standpoint is that their .38 revolvers and their .357 revolvers are made from the same steels and the same heat treating processes.

I am -NOT- advocating that handloaders should load beyond published guidelines. (however, the very skilled and connected those that DO benefit all of us, thank you Mr. Elmer Keith and your contemporaries) But a quality modern firearm can handle the stuff Buffalo Bore makes and can also handle the loads that a skilled handloader develops using established methods to attempt to replicate them.

As to the Blackhawk with a bulged chamber... far too little evidence to come to solid conclusions. A perfectly spec'd load could have bulged that chamber if there was a bore obstruction.

STORMINORMAN

Member

Hahahaha, you should see my garage!

You don't really have Jimmy Hoffa in there, do you...?

Cheers!

SuperMan

Member

Several points to consider...

First, the original and still made FBI .38 Special 158 grain LSWC-HP load as made by Winchester, Remington and Federal is not even close to the to the BB +P rated round. It doesn't even go as fast as the BB Standard Pressure round. From the Big Three, the factory rounds run 900-950 fps tops...the standard pressure BB loads are rated at 970 fps. The +P rounds are much more like the original .38-44 rounds that were in the 1100+ fps range developed back in the 1930s for the S&W Heavy Duty.

The bullets used are also very different. Although both are plain lead, the Big Three loadings all use an alloyed swaged plain lead bullet. The alloy had to be kept hard enough to not lead excessively. Depending on the manufacturer this also hindered expansion. Some bullets had the reputation of doing a better job than others.

BB on the other hand uses a cast lead HP with a gas check. This allows a softer alloy without having to worry about leading. They also cost more to make.

The other thing to consider is the advancement of steels and heat treating of the .38 Special firearms being currently manufactured. The early .38 Specials and many made through the 1960s were not of the same strength as those made today. But because of "liability" the Big Three won't make ammo for the general public for fear that one of their "hot" rounds finds it way into a 1950s vintage Saturday Night Special and they get sued.

I've been reloading handgun ammunition since 1970. Was also a commercial loader for 15 years. My standard .38 Special load that uses a Lyman/Thompson gas checked bullet is just 30 fps slower than the BB +P load... Have shot tons of this ammo out everything from snubbies to N-frames with zero issues. It isn't any hotter because I don't need it any hotter.

And as to the strength of J-frames...ask yourself the question, if S&W and Ruger can make J size guns in 9mm that will take SAMMI Spec 35K PSI loads why is it dangerous to run a .38 Special out of the same gun at 20K PSI...because a lawyer told you so....I'd carry the BB +P round in my guns any time...not so with the Big Three...

Bob

[ame]https://www.youtube.com/watch?v=GTJYsc6PdEM[/ame]

First, the original and still made FBI .38 Special 158 grain LSWC-HP load as made by Winchester, Remington and Federal is not even close to the to the BB +P rated round. It doesn't even go as fast as the BB Standard Pressure round. From the Big Three, the factory rounds run 900-950 fps tops...the standard pressure BB loads are rated at 970 fps. The +P rounds are much more like the original .38-44 rounds that were in the 1100+ fps range developed back in the 1930s for the S&W Heavy Duty.

The bullets used are also very different. Although both are plain lead, the Big Three loadings all use an alloyed swaged plain lead bullet. The alloy had to be kept hard enough to not lead excessively. Depending on the manufacturer this also hindered expansion. Some bullets had the reputation of doing a better job than others.

BB on the other hand uses a cast lead HP with a gas check. This allows a softer alloy without having to worry about leading. They also cost more to make.

The other thing to consider is the advancement of steels and heat treating of the .38 Special firearms being currently manufactured. The early .38 Specials and many made through the 1960s were not of the same strength as those made today. But because of "liability" the Big Three won't make ammo for the general public for fear that one of their "hot" rounds finds it way into a 1950s vintage Saturday Night Special and they get sued.

I've been reloading handgun ammunition since 1970. Was also a commercial loader for 15 years. My standard .38 Special load that uses a Lyman/Thompson gas checked bullet is just 30 fps slower than the BB +P load... Have shot tons of this ammo out everything from snubbies to N-frames with zero issues. It isn't any hotter because I don't need it any hotter.

And as to the strength of J-frames...ask yourself the question, if S&W and Ruger can make J size guns in 9mm that will take SAMMI Spec 35K PSI loads why is it dangerous to run a .38 Special out of the same gun at 20K PSI...because a lawyer told you so....I'd carry the BB +P round in my guns any time...not so with the Big Three...

Bob

[ame]https://www.youtube.com/watch?v=GTJYsc6PdEM[/ame]

Last edited:

Rammer Jammer

Member

Some guys just have to tinker, whether its guns, cars, carpentry etc.

We all know a guy who buys a new gun, starts "upgrading" it before they've ever shot it and then wonders why iits unreliable.

I reload for costs savings. But have no interest in working up loads for SD or modding my guns much beyond changing grips or sights.

We all know a guy who buys a new gun, starts "upgrading" it before they've ever shot it and then wonders why iits unreliable.

I reload for costs savings. But have no interest in working up loads for SD or modding my guns much beyond changing grips or sights.

boatbum101

Member

Ammo mfgers buy & produce in huge amounts . Every time propellant lot changes so does charge weight , which is determined by pressure testing . Lot to lot variation is less in " cannister " grade that is sold to reloaders . If you've ever used surplus powder to reload you know it can be substantial . When using such the sage advice of working up loads with any component change becomes even more necessary . If one wants that kind of performance one pays the price . Cast HP's are wonderfully effective if alloy selected is matched to impact velocity & also ductile to not shatter / shed . If you're gonna push 'em gaschecks make life easier . It's much easier to get repeatable bullet performance from jacketed . Cast bullets will deliver exactly what one's willing to invest . Those willing to tailor to fit their use rarely shoot jacketed .

- Joined

- Aug 9, 2005

- Messages

- 9,251

- Reaction score

- 11,470

Ammo mfgers buy & produce in huge amounts . Every time propellant lot changes so does charge weight , which is determined by pressure testing . Lot to lot variation is less in " cannister " grade that is sold to reloaders . If you've ever used surplus powder to reload you know it can be substantial . When using such the sage advice of working up loads with any component change becomes even more necessary . If one wants that kind of performance one pays the price . Cast HP's are wonderfully effective if alloy selected is matched to impact velocity & also ductile to not shatter / shed . If you're gonna push 'em gaschecks make life easier . It's much easier to get repeatable bullet performance from jacketed . Cast bullets will deliver exactly what one's willing to invest . Those willing to tailor to fit their use rarely shoot jacketed .

There is no advantage (accuracy, velocity, etc.) in using a jacketed bullet in any handgun cartridge over a cast bullet IF the cast bullet is of the proper size and alloy mix for the intended load. However, few are willing to go to the trouble (not nearly as much as some think) nowadays to make the best cast bullet for the load and for their gun(s).

I enjoy experimenting more than most, but a fanatical and tormenting need to duplicate Buffalo Bore loads and to a similar extent "FBI loads" escapes me.

Why not simply use paper published load data and be satisfied with the results? You can still find some pretty warm +P data. This is especially applicable when dealing with older steel and alloy J-frame .38s and Colt snub nose guns. Most of these are probably stretched pretty close to design limits with hot ammo. No, you may not destroy a gun by shooting it with heavy loads, at least not right away, but they will take their toll. Abused by shooting much of this ammo will wear these guns out prematurely.

Consider a different revolver in a more powerful chambering if the all consuming need for power won't dissipate.

- Joined

- Feb 29, 2000

- Messages

- 2,297

- Reaction score

- 2,483

I like that gent's use of bologna at the face of his Fackler box. Much more consistent medium that pieces of whole meat as Paul Harrel uses. Danged bit cheaper, too. Ditto the fiber-board, vs. the regular lumber.

AJ

US Veteran

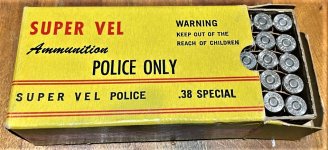

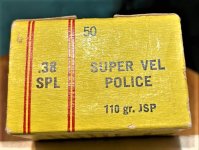

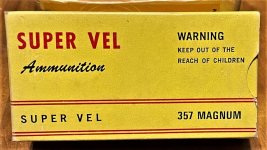

Not FBI loads, but probably pretty stout........

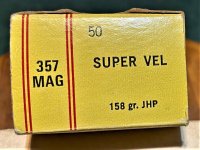

While not the FBI loads from Buffalo Bore, I have a feeling these are probably right stout! I have some 158 grain ammo from the same manufacturer, but it is .357 Magnum.

While not the FBI loads from Buffalo Bore, I have a feeling these are probably right stout! I have some 158 grain ammo from the same manufacturer, but it is .357 Magnum.

Attachments

Last edited:

AJ

US Veteran

- Joined

- Aug 9, 2005

- Messages

- 9,251

- Reaction score

- 11,470

While not the FBI loads from Buffalo Bore, I have a feeling these are probably right stout! I have some 158 grain ammo from the same manufacturer, but it is .357 Magnum.

I'd have to look up the data to be sure, but I think CUP pressure on this loads was around 22,000 - 24,000, fifty years ago, according to testing done in the Super Vel lab. They also tested the Norma 110 grain - the hottest .38 Special factory load ever as far as I am aware. It had a pressure of around 27,000. It's important to remember that this was before the +P designation.

At the time, if it said .38 Special on the box, many fired hot factory ammo in any .38 Special revolver. Never heard of one being destroyed, but I'll bet there are a few loose .38 revolvers out there. Refreshingly, it was impossible to ask "Can I fire +P in my gun?" and there were no arguments about doing so either.

- Joined

- Apr 4, 2006

- Messages

- 19,798

- Reaction score

- 31,645

Buffalo Bore has made a regular routine of shirking SAAMI so there isn't one good reason to expect that ANY particular Buffalo Bore product aligns with industry standards.

At the same time...

For a modern S&W, the only thing that makes sense from a manufacturing-for-profit standpoint is that their .38 revolvers and their .357 revolvers are made from the same steels and the same heat treating processes.

I am -NOT- advocating that handloaders should load beyond published guidelines. (however, the very skilled and connected those that DO benefit all of us, thank you Mr. Elmer Keith and your contemporaries) But a quality modern firearm can handle the stuff Buffalo Bore makes and can also handle the loads that a skilled handloader develops using established methods to attempt to replicate them.

As to the Blackhawk with a bulged chamber... far too little evidence to come to solid conclusions. A perfectly spec'd load could have bulged that chamber if there was a bore obstruction.

I am curious as to how you know Buffalo Bore routinely exceeds SAAMI spec's.

nicky4968

Member

If you want to load the loads Buffalo Bore loads, buy the factory and have done with it.

I am curious as to how you know Buffalo Bore routinely exceeds SAAMI spec's.

Buffalo Bore routinely markets ammo with +P labels on them that are not recognized by SAAMI or any SAAMI member. .380 Auto+P doesn't exist in the standards that all American gunmakers use and all American ammo makers use either, but Beefalo Bore makes it.

Some may think I'm splitting hairs. I'll disagree with vigor. I have fantastic respect for SAAMI. I believe that anyone who steps back and pauses to see the value in a respected industry standard might agree.

I am wondering if this is hotter than the FBI load? Knowing the rep of Jurras and the old Super Vel company, I have a feeling it is......

That is some really hot stuff, probably nastier than BB. They used 9 mm (.355") bullets in their 357 Magnum and 39 Special ammo in an attempt to keep pressure down and velocity up.

I'd have to look up the data to be sure, but I think CUP pressure on this loads was around 22,000 - 24,000, fifty years ago, according to testing done in the Super Vel lab. They also tested the Norma 110 grain - the hottest .38 Special factory load ever as far as I am aware. It had a pressure of around 27,000. It's important to remember that this was before the +P designation.

At the time, if it said .38 Special on the box, many fired hot factory ammo in any .38 Special revolver. Never heard of one being destroyed, but I'll bet there are a few loose .38 revolvers out there. Refreshingly, it was impossible to ask "Can I fire +P in my gun?" and there were no arguments about doing so either.

Keep in mind that any pressure data that a lab comes up with is only true for that ammo in that pressure testing equipment on that day. It is anybody's guess what the actual pressure is when fired in any particular revolver, and there is no way to test it.

- Joined

- Aug 9, 2005

- Messages

- 9,251

- Reaction score

- 11,470

Keep in mind that any pressure data that a lab comes up with is only true for that ammo in that pressure testing equipment on that day. It is anybody's guess what the actual pressure is when fired in any particular revolver, and there is no way to test it.

There is much truth in your comment, but we get to a point of practicality where some assumptions and estimations can be accepted as reasonable. I think the testing Mr. Jurras did in his lab was reasonably accurate; at least nothing indicates otherwise.

Along this same line, there is a comprehensive article in HANDLOADER magazine from the early '70s written by the late Bill Caldwell, a ballistics guy with Speer. I'd have to dig the article out because I haven't read it in a good while, but I do recall one key point that Caldwell discovered in his test work. It appeared that the pressure from a standard revolver may actually be a little higher than that obtained with a pressure barrel.

Of course, that was fifty years ago and pressure measuring is now a bit more sophisticated and probably more accurate, but at least some of what Caldwell mentioned is probably valid today.

Last edited:

I've got a shelf full of loading manuals. 38special has wide spectrum of loads. If you can't find something that floats your boat, I suggest buying a 357 mag.

The same thing with rifle ammunition. It never fails, gun is just been taken out of box and they are talking about hot rodding it up to the next caliber up the ladder.

I look at it this way. Two dead bodies laying on the ground. They are both the same percentage of dead. I would be more concerned about revolver failing at critical time after using it for testing hot loads.

I been loading since 1960s. Grew up when Magnums were coming out. You had to shoot everything full blast. I went through all that and one day realized what do you need that for? In most cases you don't. For stopping things with blood pumps heavy bullets at lower velocity work well.

The same thing with rifle ammunition. It never fails, gun is just been taken out of box and they are talking about hot rodding it up to the next caliber up the ladder.

I look at it this way. Two dead bodies laying on the ground. They are both the same percentage of dead. I would be more concerned about revolver failing at critical time after using it for testing hot loads.

I been loading since 1960s. Grew up when Magnums were coming out. You had to shoot everything full blast. I went through all that and one day realized what do you need that for? In most cases you don't. For stopping things with blood pumps heavy bullets at lower velocity work well.

Similar threads

- Replies

- 40

- Views

- 2K

- Replies

- 23

- Views

- 1K

- Replies

- 44

- Views

- 2K