Since commercial coated bullets are fairly new and a small percentage of revolveros shoot their rounds thru carbines,

you may be the one to tell us how they perform.

I don't think I have ever shot cast bullets thru my carbines as I had not yet discovered the gas check bullet back then.

Now that's my favorite 44 mag load (Cast Perf. 260 WFNGC, 18-19 grains 2400)

but I still have quite a few jacketed rounds loaded up.

I may tear down the ball powder ones as I have found some of them with congealed powder.

Ball powder doesn't store well when compressed.

Got my only stuck bullet firing one of those old loads.

These are a couple of my favorite carbines.

I have a couple of other W94's but they are not built as well.

The '92 is the perfect action for the 44 Mag having been designed for revolver rounds in the first place.

I am still waiting for Bighorn Armory to come out with a version of their 89 in 445 Supermag.

It is specifically designed for the big 1.6" revolver rounds.

I am making do with an Encore for now.

It shoots cast bullets just fine up to 1900 fps (that Cast Perf 260 I mentioned).

When I get some heavier coated bullets, I'll let you know how they work at high velocity.

They may still want a gas check as you get above 1500 fps.

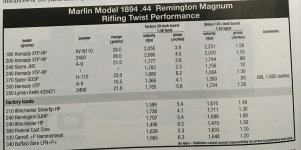

As you may know the twist rates in 44 carbines can vary from 1/38" down to 1/20" and below.

This is going to affect accuracy and stability more than the style of bullet.

Brian Pearce did an eye opening test in a recent edition of Rifle using 44 mag carbines of different twist rates.

We get a lot better performance out of the 444 Marlin 1/38" barrels than he did with the magnum as the velocities are much higher.

Don't know much about the 357 twist rates.