John Hill

Member

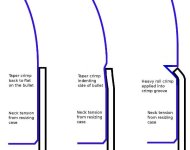

I am confused about how much to crimp my 38 special cases using 158 grain lead semi wad cutter bullets. The SAAMI charts of the specs do not address this question. Since I flare the cases just enough to start the bullet, do I use the crimping die to just close or "tighten the flared area till it just fits nicely in my revolver cylinder or do I want to actually roll it inward some? I wrinkled half a box of rounds by having the crimping die adjusted too low. Any advice is appreciated.

thanks

John

thanks

John