Longman

Member

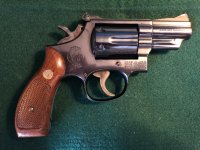

I have a 19-4 2.5" that gets casings badly stuck on all types of ammo I've tried. 357 magnum loads and 38 special get stuck to the point that the casings have to be hammered out. I've tried different brands, brass casings, even 38 special steel casings, and they are all sticking with the same severity. The casings end up with a visible bulge and striations from about mid-point down to the base, just above the rim.

I took it to a local gunsmith and was told, after 3 weeks, that "Upon inspection I noticed the cylinder is over worn. This firearm needs a new cylinder." Does this issue match with the cylinder being worn?

I'm also getting conflicting answers on what cylinders are compatible with the 19-4. Smith & Wesson customer service says to go with cylinders from 19-4 up to 19-8, while Numrich's says that cylinders from the 19 no dash to 19-3 will work with the 19-4. So which one is correct?

I took it to a local gunsmith and was told, after 3 weeks, that "Upon inspection I noticed the cylinder is over worn. This firearm needs a new cylinder." Does this issue match with the cylinder being worn?

I'm also getting conflicting answers on what cylinders are compatible with the 19-4. Smith & Wesson customer service says to go with cylinders from 19-4 up to 19-8, while Numrich's says that cylinders from the 19 no dash to 19-3 will work with the 19-4. So which one is correct?