The small amt of silver added to the tin (sometimes lead/tin) alloy in soft solder increases it's strength quite a bit (shear strength?)

It can lower the melting point of the alloy as well.

One thing I don't care for when using it is that the Silver in the mix makes the solder stay visible as a bright white substance.

Usually the 'soldering line' where the parts are joined together.

It makes little difference in most applications but on a firearm that is blued finished, that bright white line is not appreciated by customers.

I did a couple re-rib jobs some yrs ago when the stuff first came around and though it worked just fine, that white thin line up and down both sides of the rib in many places didn't look good at all.

So I stripped them and re-did them with 50-50 lead/tin and continue to use that. Plenty strong for that job and the Lead/Tin solder does oxidize down to a dark grey color in short order, So against a blued surface it does't scream 'look at me'

I used the same paste flux for either and seemed to work just fine.

The Tin/Silver hides very nicely on Stainless work.

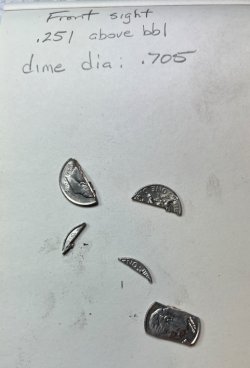

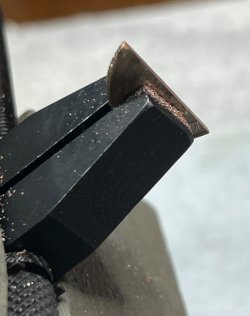

If the OP plans to make a front sight of silver with 3 pieces sandwiched together, the Tin/Silver solder would likely hide quide nicely against the Silver Dime metal where soldered to the steel bbl when blued.

Fixing up those old hard rubber grips, grip caps and butt plates is easily done with black colored epoxy.

On the grip frame as here, I usually take a piece of Saran Wrap and place it over the grip frame first.

Stretch it tight so there are no wrinkles in it where it lays on the frame, then place the broken grip down onto it on one side. Clamp in place.

Then pull the wrap over the backstrap, grip strap and butt away from the grip panel. That will protect those metal surfaces from the epoxy and give a nice clean sharp edge to the casting for those shapes.

Scotch tape down the wrap to hold it in place if needed.

..I usually do only one side at a time so I can be sure the Wrap isn't wrinkled underneath the grip.

Support the pistol in a vise so when the epoxy is added to area, it does run away on you and let it set up.

It helps to rough up the inner surfaces of the broken panel where the epoxy is to attach to. Old breaks usually are coated with dirt and oil from decades of cary and use.

Scrape them clean with the point of a pocket knife carefully is my usual method. Directional lines mean nothing, just get the surface clean and roughed up.

The stuff will usually have a brown color underneath.

It can lower the melting point of the alloy as well.

One thing I don't care for when using it is that the Silver in the mix makes the solder stay visible as a bright white substance.

Usually the 'soldering line' where the parts are joined together.

It makes little difference in most applications but on a firearm that is blued finished, that bright white line is not appreciated by customers.

I did a couple re-rib jobs some yrs ago when the stuff first came around and though it worked just fine, that white thin line up and down both sides of the rib in many places didn't look good at all.

So I stripped them and re-did them with 50-50 lead/tin and continue to use that. Plenty strong for that job and the Lead/Tin solder does oxidize down to a dark grey color in short order, So against a blued surface it does't scream 'look at me'

I used the same paste flux for either and seemed to work just fine.

The Tin/Silver hides very nicely on Stainless work.

If the OP plans to make a front sight of silver with 3 pieces sandwiched together, the Tin/Silver solder would likely hide quide nicely against the Silver Dime metal where soldered to the steel bbl when blued.

Fixing up those old hard rubber grips, grip caps and butt plates is easily done with black colored epoxy.

On the grip frame as here, I usually take a piece of Saran Wrap and place it over the grip frame first.

Stretch it tight so there are no wrinkles in it where it lays on the frame, then place the broken grip down onto it on one side. Clamp in place.

Then pull the wrap over the backstrap, grip strap and butt away from the grip panel. That will protect those metal surfaces from the epoxy and give a nice clean sharp edge to the casting for those shapes.

Scotch tape down the wrap to hold it in place if needed.

..I usually do only one side at a time so I can be sure the Wrap isn't wrinkled underneath the grip.

Support the pistol in a vise so when the epoxy is added to area, it does run away on you and let it set up.

It helps to rough up the inner surfaces of the broken panel where the epoxy is to attach to. Old breaks usually are coated with dirt and oil from decades of cary and use.

Scrape them clean with the point of a pocket knife carefully is my usual method. Directional lines mean nothing, just get the surface clean and roughed up.

The stuff will usually have a brown color underneath.

Last edited: