In this thread we're going to be working on an abused 64-5 and learning about refinishing stainless steel. Things are going a little slow around here since the heart attack so an easy set of projects seemed to be in order. I did manage to survive "the treadmill from hell" yesterday, so things are looking up.

Maybe I should have called this "Short and Shinies" because there are actually two, but we're really only going to concentrating on just one. I got this pair cheap because they've been overseas and when they came home, the graffiti artists at CAI did this to them:

I've done several threads involving barrel swaps and caliber changes, so I won't repeat all that and we'll just say that both barrels fell off and were replaced with better examples. The original barrels still have value and were added to the pile to be used as practice material for when I learn how to shorten barrels or do slab-sides...or both.

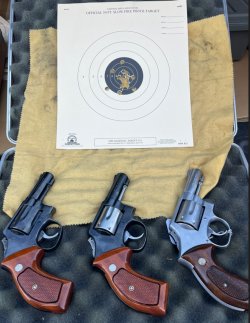

Here's the obligatory "gun about to become something else" picture:

Quite a few of my projects don't really have a plan. I just start and let the gun take me to wherever we end up. With these two, one of them wanted to stay as a 4" .38 Special and the other wanted to become a 3" .357 Magnum. A 64.5 instead of a 64-5 is probably a good way to put it.

Barrels were swapped, a cylinder was fitted, action jobs were done, and we were off to the range for a function check before going any farther.

The barrels seem to be on reasonably straight....

I did a few drills with the 64.5 and decided that it had enough potential that it deserved some extra attention.

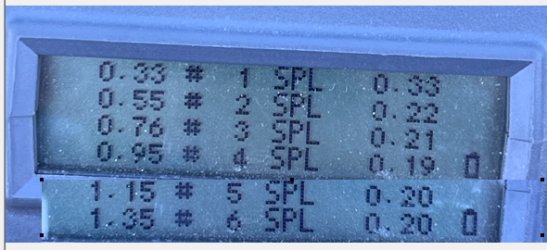

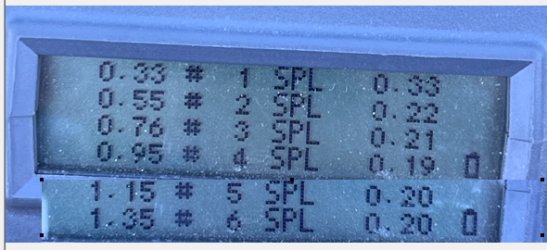

The timer picture looks a bit weird because it's two pictures spliced together...it only shows 4 shots at a time. Six shots in under 1.5 seconds from a low ready at 5 yards. This one may have to stay.

What extra attention does it need? All cosmetic. It functions wonderfully, but it's been dropped. Or used as a hammer. Or both. That's coming up next.....

Maybe I should have called this "Short and Shinies" because there are actually two, but we're really only going to concentrating on just one. I got this pair cheap because they've been overseas and when they came home, the graffiti artists at CAI did this to them:

I've done several threads involving barrel swaps and caliber changes, so I won't repeat all that and we'll just say that both barrels fell off and were replaced with better examples. The original barrels still have value and were added to the pile to be used as practice material for when I learn how to shorten barrels or do slab-sides...or both.

Here's the obligatory "gun about to become something else" picture:

Quite a few of my projects don't really have a plan. I just start and let the gun take me to wherever we end up. With these two, one of them wanted to stay as a 4" .38 Special and the other wanted to become a 3" .357 Magnum. A 64.5 instead of a 64-5 is probably a good way to put it.

Barrels were swapped, a cylinder was fitted, action jobs were done, and we were off to the range for a function check before going any farther.

The barrels seem to be on reasonably straight....

I did a few drills with the 64.5 and decided that it had enough potential that it deserved some extra attention.

The timer picture looks a bit weird because it's two pictures spliced together...it only shows 4 shots at a time. Six shots in under 1.5 seconds from a low ready at 5 yards. This one may have to stay.

What extra attention does it need? All cosmetic. It functions wonderfully, but it's been dropped. Or used as a hammer. Or both. That's coming up next.....

Last edited: