Bloodhound

Member

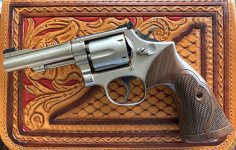

I have a 4 inch Model 28 S serial number that makes it about 1968. It was a carry gun for sure with holster wear to the blue, but not shot much, still a very tight gun. It is a fine shooter and doesn't need to be refinished or hard chromed. But when I started as a Sheriff's Deputy I was mentored by a retired Sheriff's Deputy and his duty gun was a Model 28. Due to an incident while arresting a guy, he ended up tossing his gun off the dock into the ocean, where they were to avoid the bad guy getting it. The dive team recovered the gun and a company in the area cleaned it and hard chromed it for him.

I shot that gun several times and it is the reason I wanted a 28 in my collection. His gun went down the road to an unknown buyer after he passed away.

So I am swaying back and forth on getting my 28 hard chromed and if so who to do the work.

Here are a few pics of my gun.

I shot that gun several times and it is the reason I wanted a 28 in my collection. His gun went down the road to an unknown buyer after he passed away.

So I am swaying back and forth on getting my 28 hard chromed and if so who to do the work.

Here are a few pics of my gun.

Attachments

Last edited: